Pulp and Paper Products

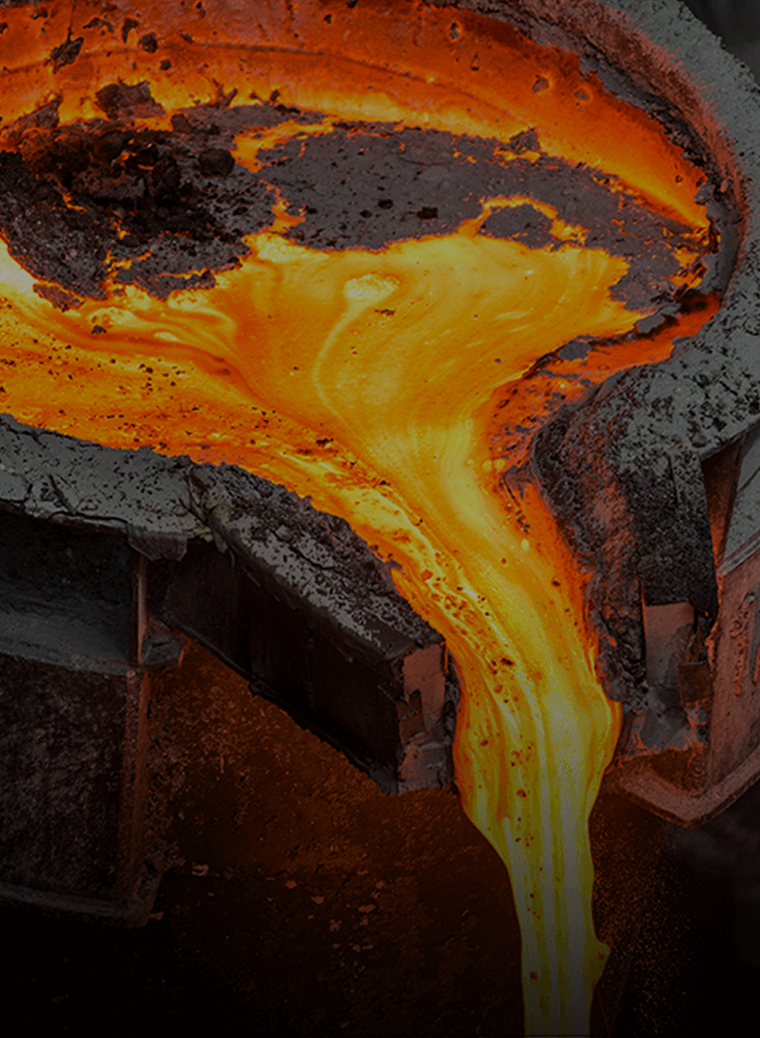

Paper and wood products are not just renewable, recyclable, and sustainable but are essential to everyday life. Paper packages, including boxes, paper bags, and shipping sacks, are a versatile and innovative way to transport and protect a wide array of goods. In addition to being the raw material used to make paper and packaging, wood-based pulp is a sustainable alternative to oil-based materials like plastics.

Powering The World One Pulp and Paper Fan At A Time

Tissue products are utilized daily. They are comfortable, convenient, and sustainably manufactured. Wood products are diverse: lumber is used in home-building and furniture, sawdust and woodchips become fuel, and chemically-processed wood (cellulose).

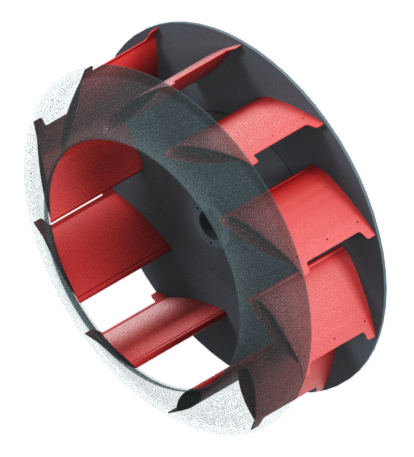

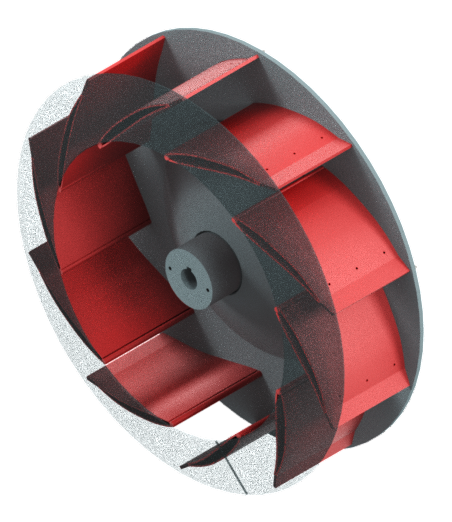

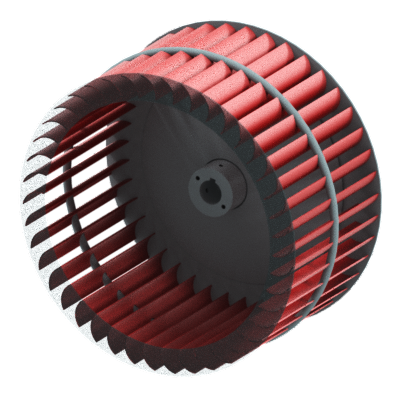

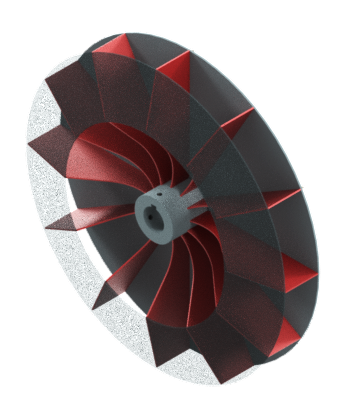

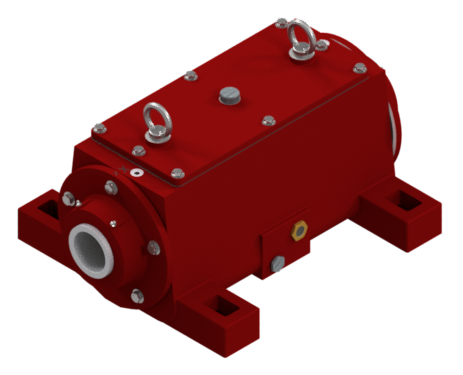

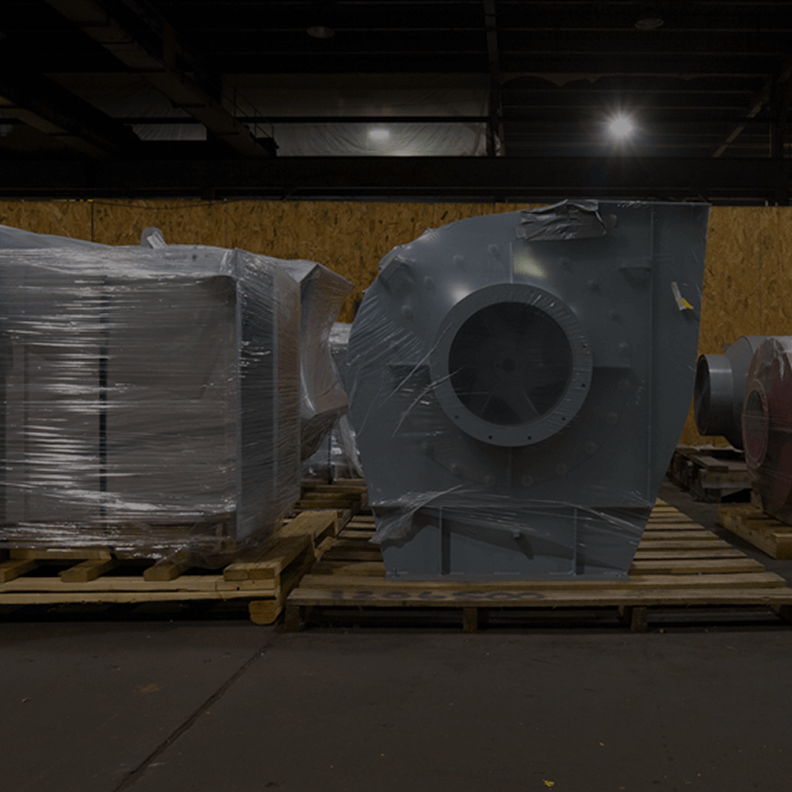

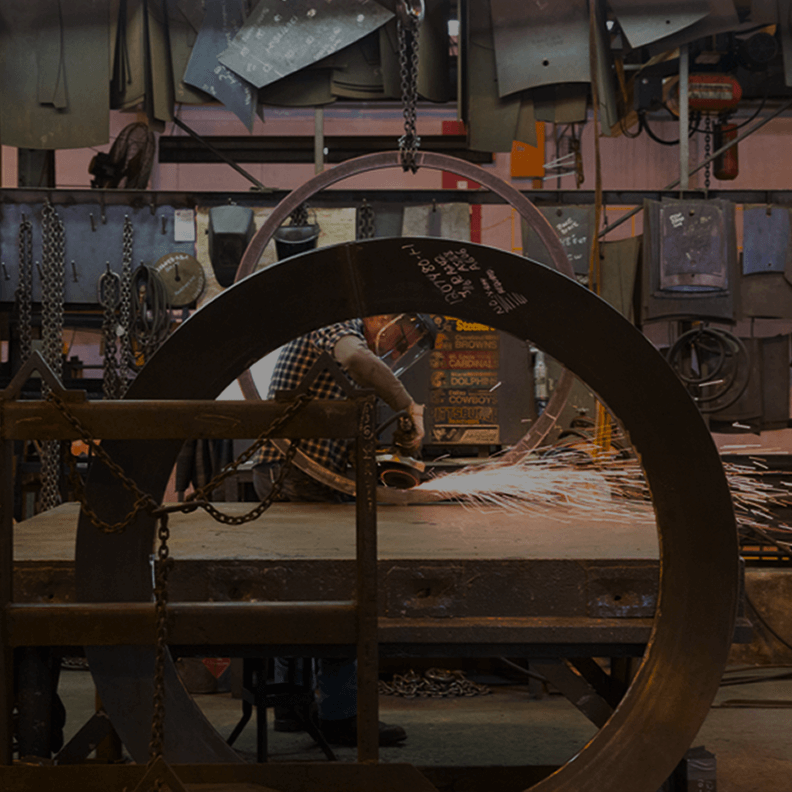

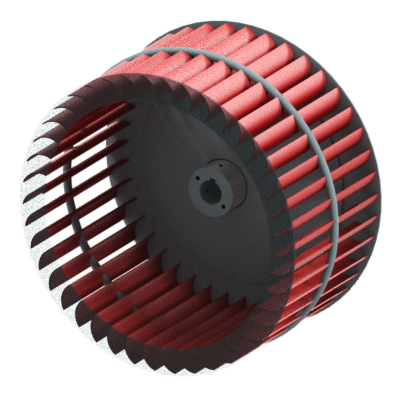

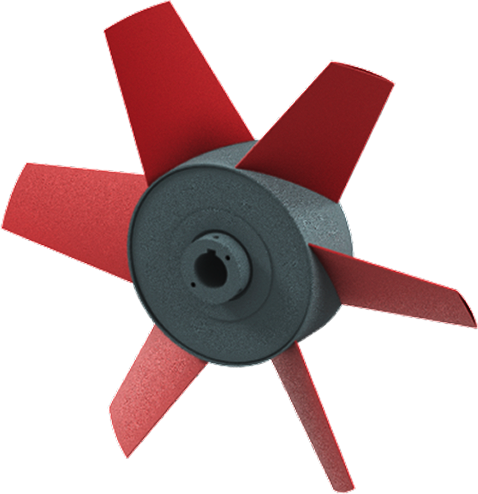

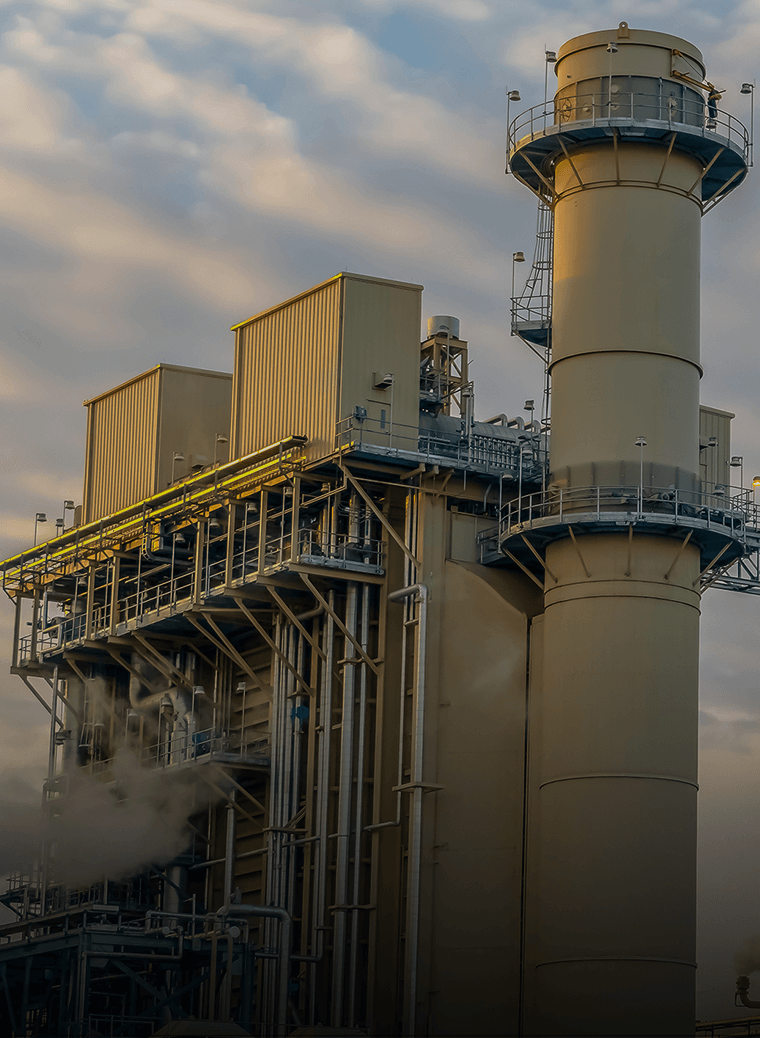

Robinson fans are utilized for a variety of applications within the paper and wood product industry, some of which are high-temperature and/or highly corrosive environments. Robinson supplies boiler-forced draft fans, combustion air fans, Through Air Drying (TAD), and Yankee Hood application fans.

Pulp and Paper Products Emergency Fan Repair

We recognize that a forced outage is a nightmare for our customers. Our brand reputation of providing market-leading technical expertise with superior customer service, we aim to minimize downtime so you can be operational asap.

Industrial

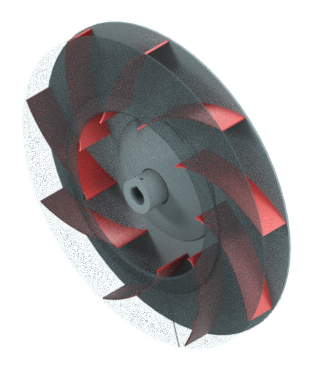

Fan Design

For Pulp and Paper

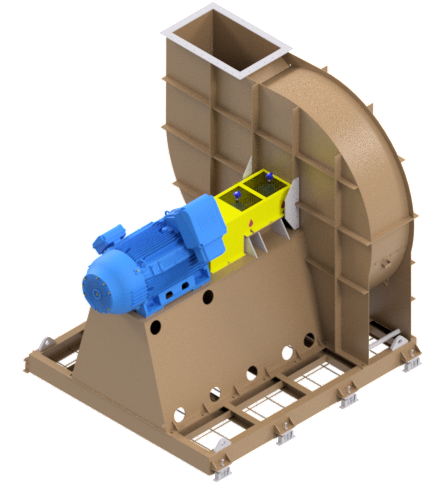

Manufacturing

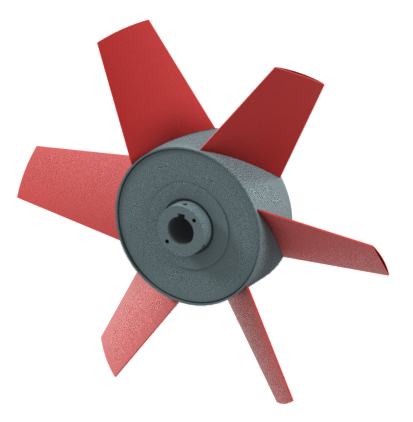

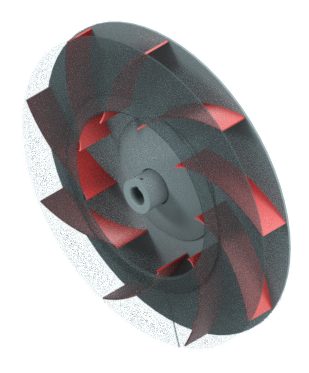

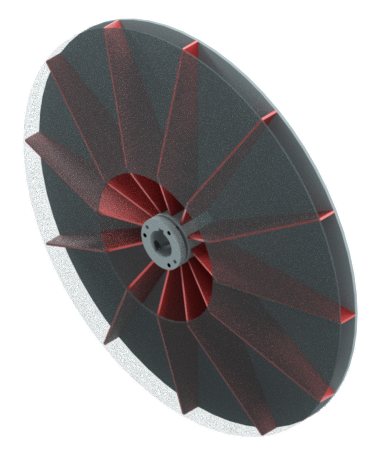

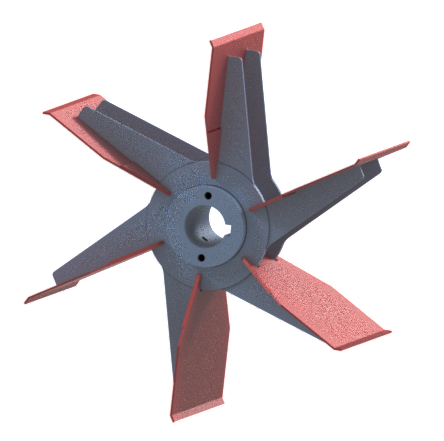

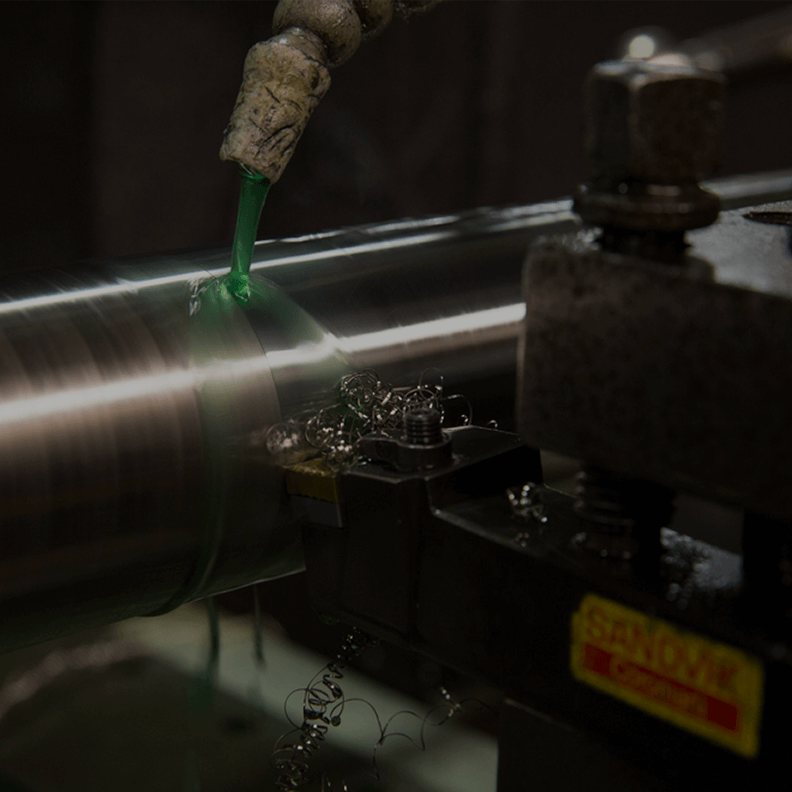

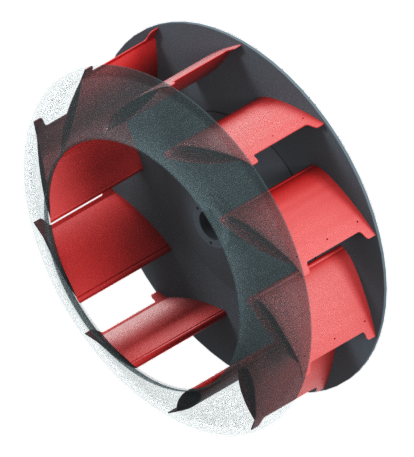

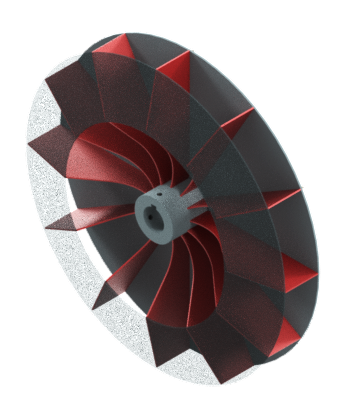

Due to our long-standing history in technical expertise and customer service, Robinson is able to custom design fans to meet our customers specific needs. There are key design considerations when selecting an industrial fan for high-temperature recirculation including but not limited to: material selection, bearings and lubrication, cooling, and performance.

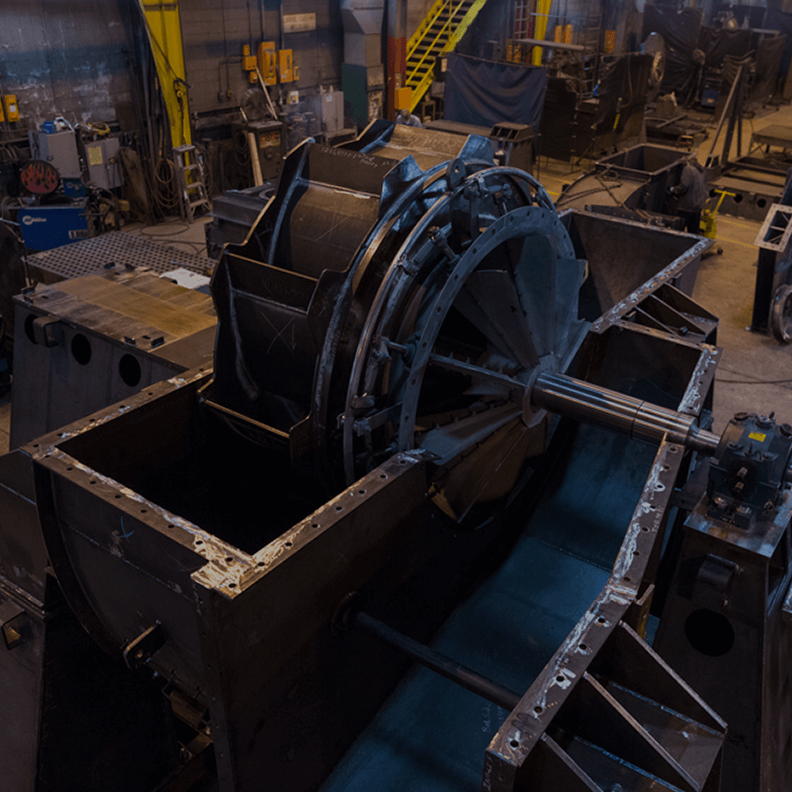

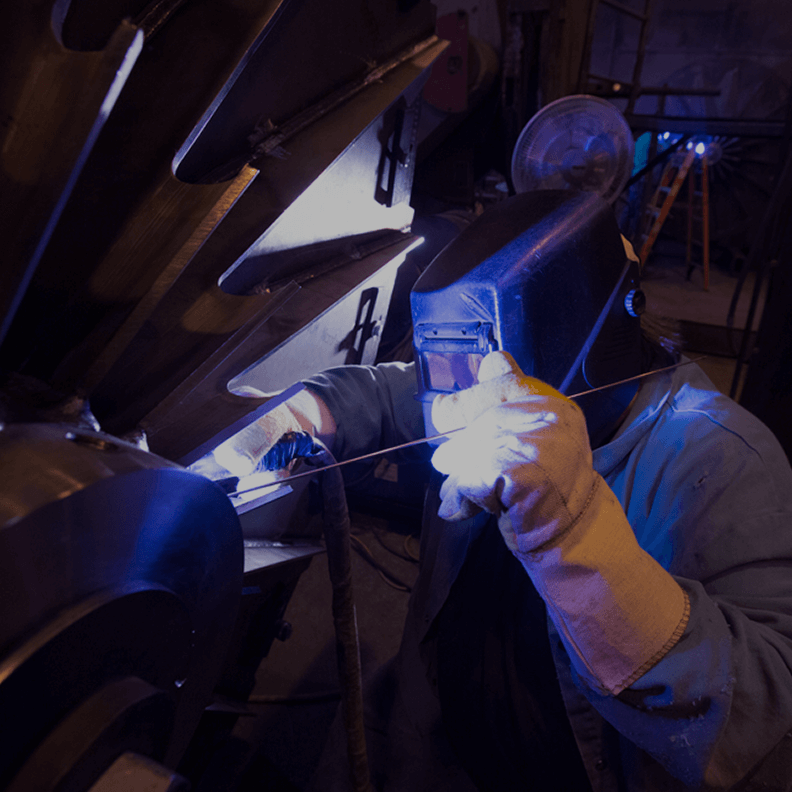

Pulp and Paper Industrial Fan Service & Repair

Combining decades-long fan expertise with best-in-class customer service, Robinson will provide full, wraparound services to ensure appropriate and cost-effective fan repair.

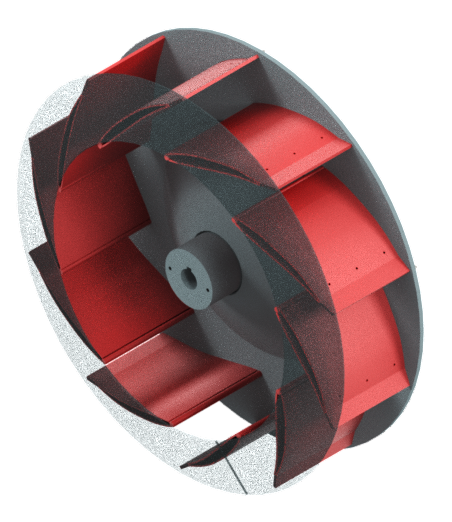

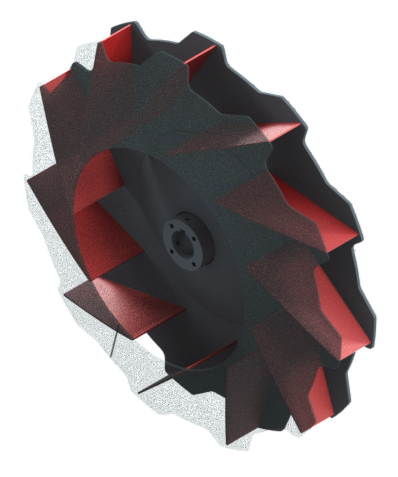

Backward Inclined Fans

Case Studies

Case Studies

Industrial Fan Products

From replacement fan parts to complete custom-designed industrial fans, we have you covered.

Pulp and Paper Industrial Fan Services

Robinson values our market-leading technical expertise as well as our outstanding customer service. We maintain these values in the services we offer to meet all of your industrial fan-related needs.

How

Can We

Help You?

How

Can We

Help You?

We work with

the biggest and best in the world

Why Robinson?

Over 130 years

of history

A sixth-generation

family-owned business,

Robinson offers unmatched

experience

Technical

Expertise &

Customization

standard fan lines, Robinson

customizes every solution to

meet specific customer needs

Top Notch

Customer Service

quality and long-term

relationships

Rapid

Response 24/7

24/7 emergency breakdown

services and a dedicated

Rapid Repair team for a quick turnaround