Steel & Aluminum

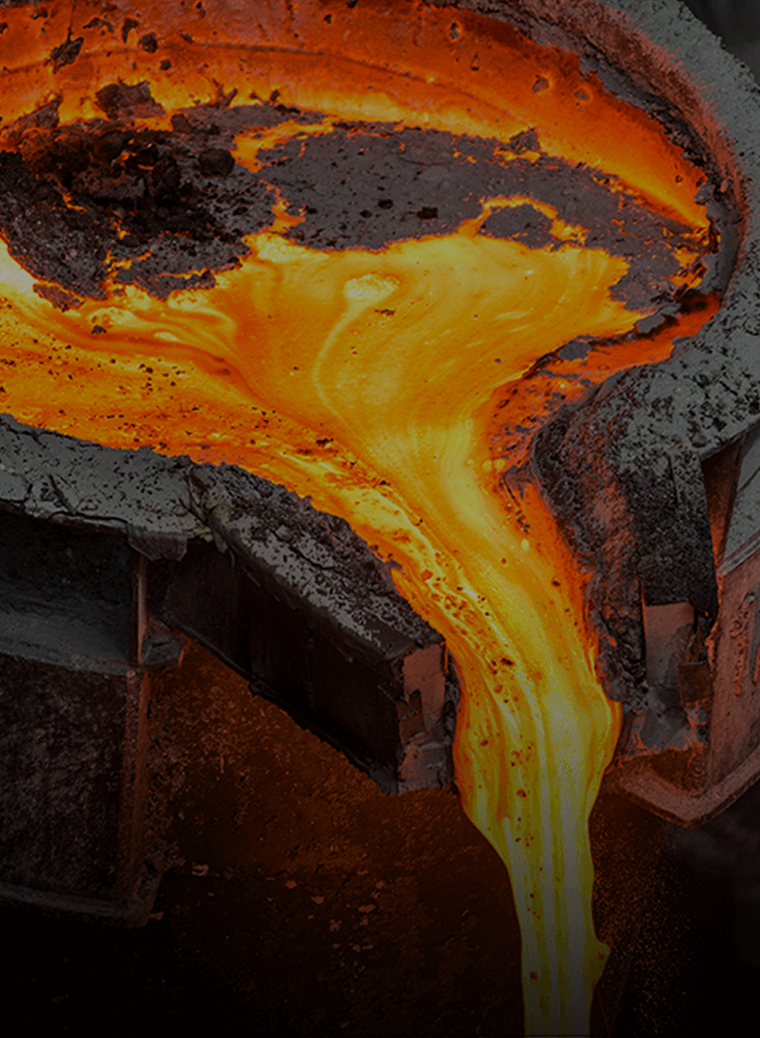

The steel and aluminum industry is a fundamental part of global manufacturing, construction, transportation, and infrastructure. These metals are essential for producing automobiles, buildings, machinery, consumer goods, and aerospace components.

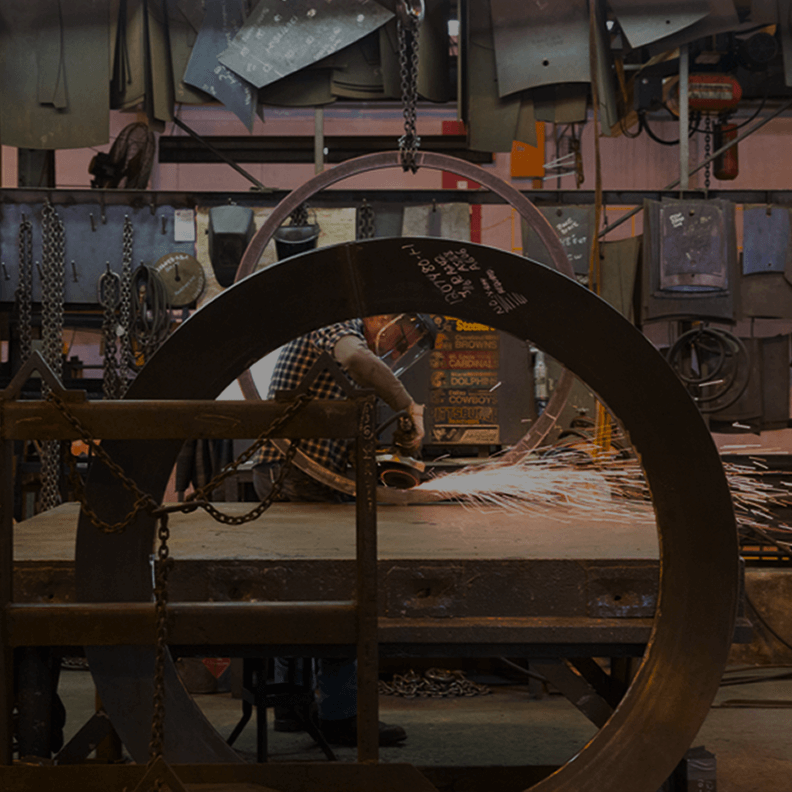

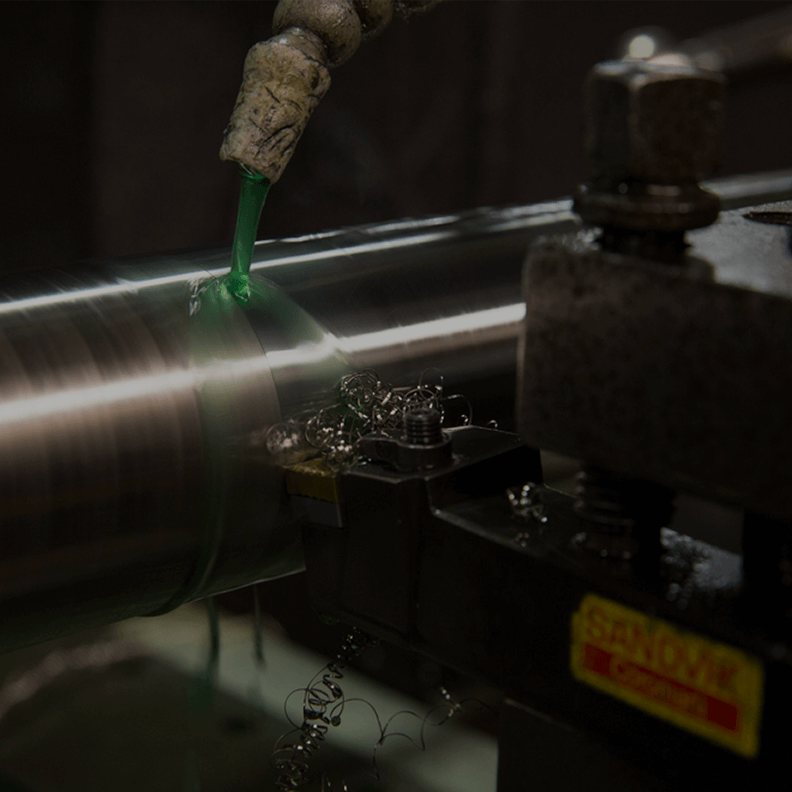

Industrial fans play a crucial role in the steel and aluminum industry, facilitating ventilation, cooling, heat treatment, fume extraction, and pollution control in high-temperature and heavy-duty environments. These fans are designed to withstand extreme conditions, including high temperatures, abrasive dust, corrosive gases, and heavy particulate loads.

Key Applications:

Combustion Air & Furnace Operations

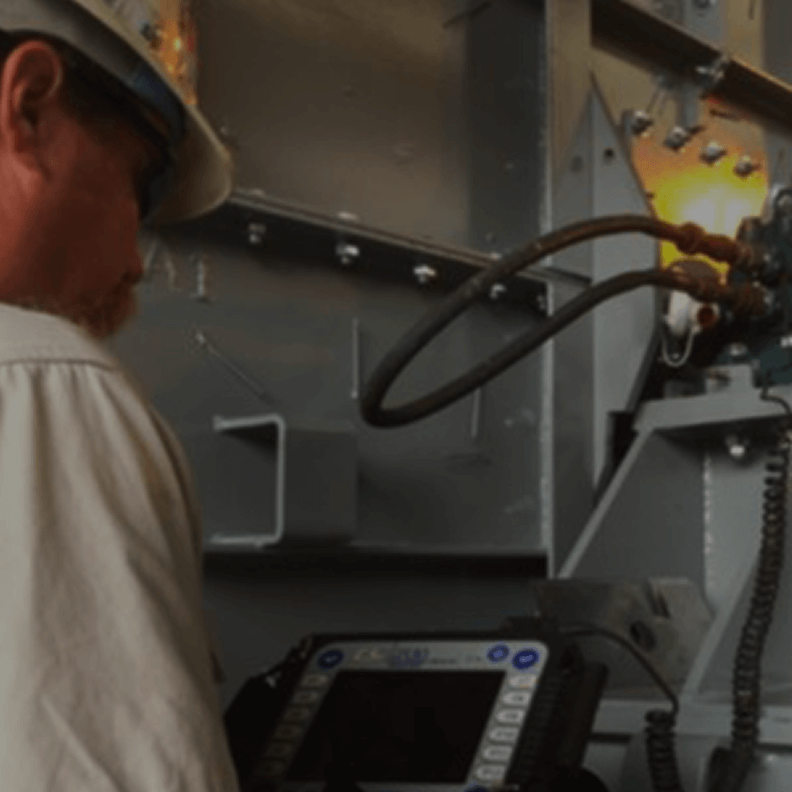

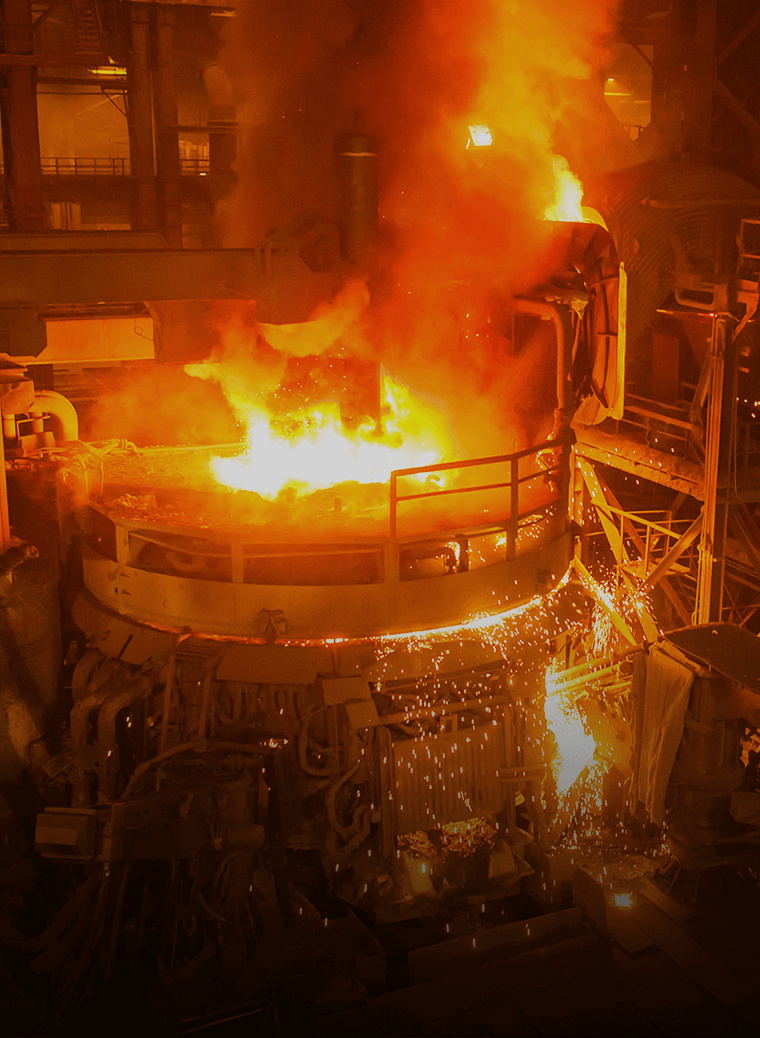

- Provide combustion air for blast furnaces, electric arc furnaces (EAFs), and reheat furnaces.

- Ensure efficient fuel burning and temperature uniformity.

Cooling & Heat Dissipation

- Used in continuous casting, rolling mills, and annealing processes to cool molten metal and finished products.

Fume & Dust Collection

- Remove metallic dust, exhaust gases, and toxic gases (CO, NOx, SOx, and VOCs) from smelting, refining, and alloy production.

- Integrated into baghouses, electrostatic precipitators (ESPs), and scrubbers for air pollution control.

Material Handling

- Fans aid in the collection of fine metal powders, alumina, and slag particles in processing plants.

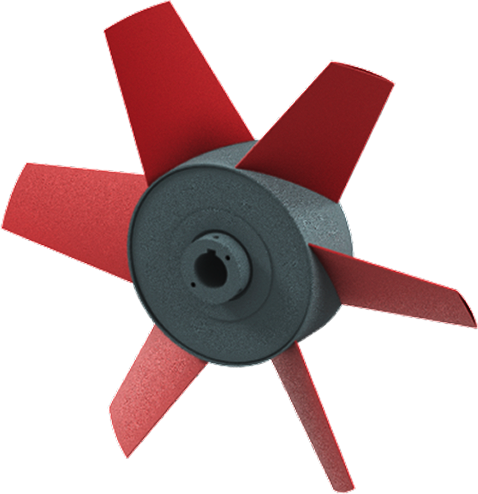

High-Temperature Air Recirculation

- High-temperature axial fans facilitate air circulation through heat treating furnaces, annealing furnaces, and other high temperature furnace applications.

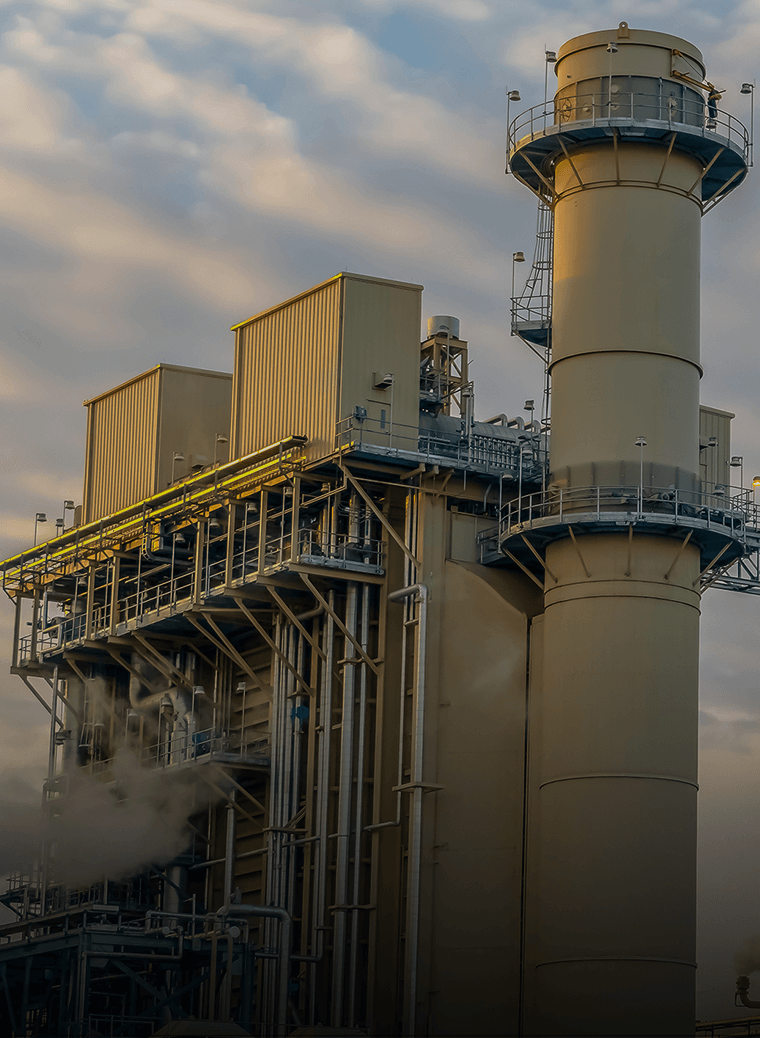

Environmental & Emissions Control

- Fans support desulfurization, carbon capture, and exhaust gas treatment.

- Fans help meet stringent environmental regulations on industrial emissions.

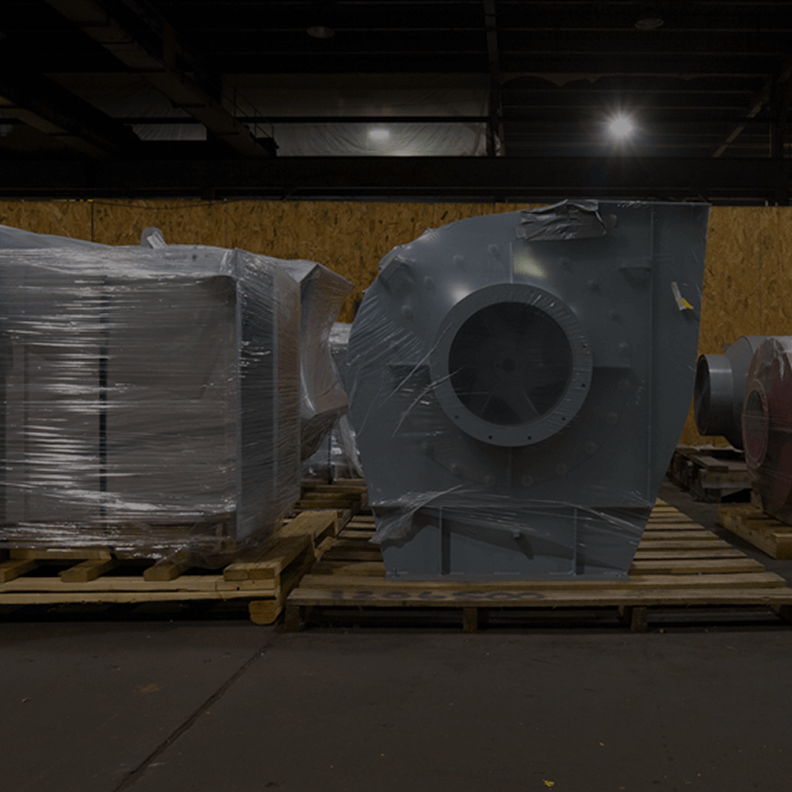

With expertise in both ferrous and non-ferrous metal production applications, Robinson provides custom-engineered solutions to the metal industry to meet existing and emerging process fan requirements. Robinson’s technical team can recommend furnace recirculation solutions that meet the specifications of any installation.

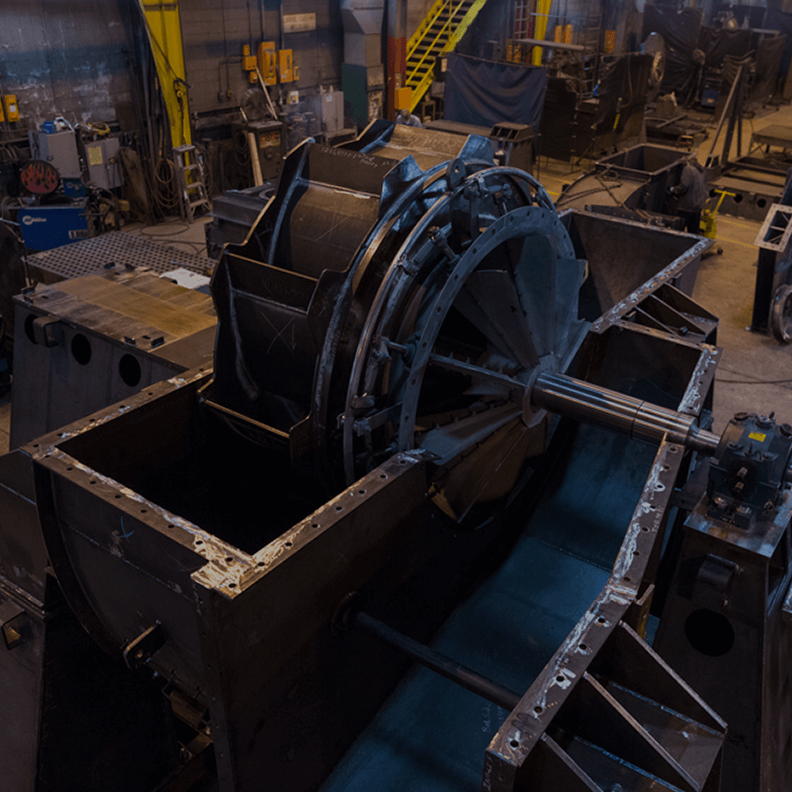

Steel & Aluminum Fan Repair

Is your fan broken or needs repair ASAP!? Contact us now for 24/7 emergency fan service.

Steel and Aluminum

Fan Design

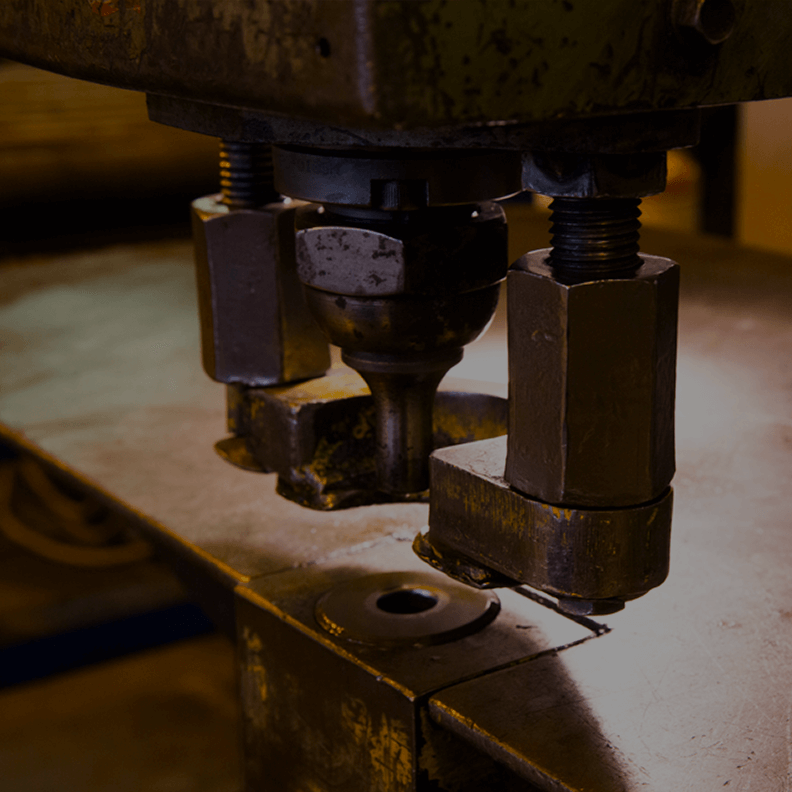

Robinson’s industry-leading custom engineering will consider customer specifications and design equipment that maximizes performance without sacrificing quality. Design considerations include: high-temperature applications, corrosion from acidic and metallic gases, high dust and particulate loads, and energy consumption concerns.

Steel and Aluminum

Fan Repair

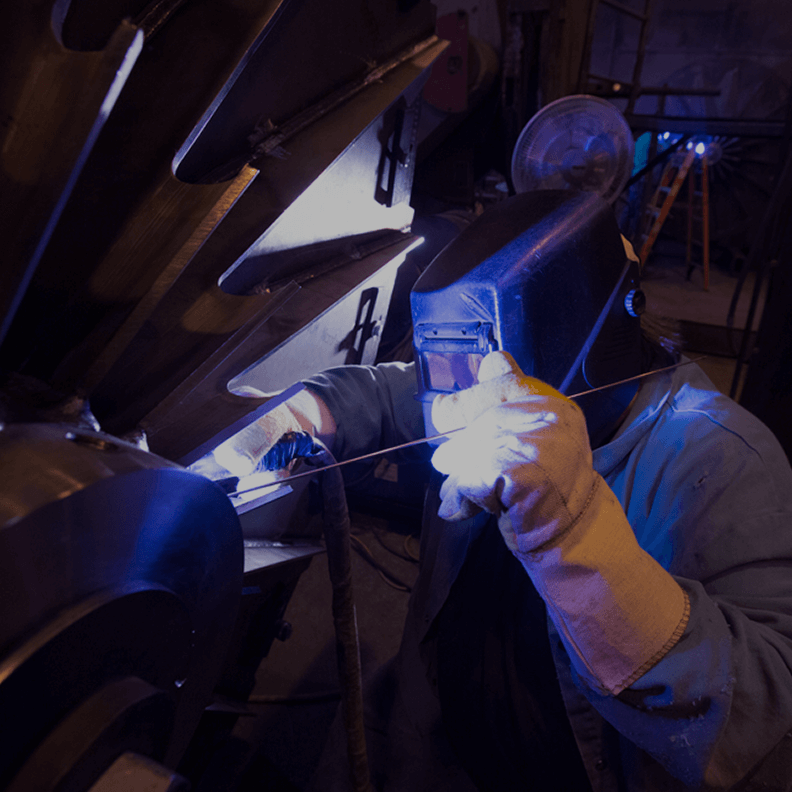

Are you experiencing vibration instability on your fan equipment? Are you noticing cracking in your fan casing? Are you experiencing overheating of your bearings resulting in shaft compromise?

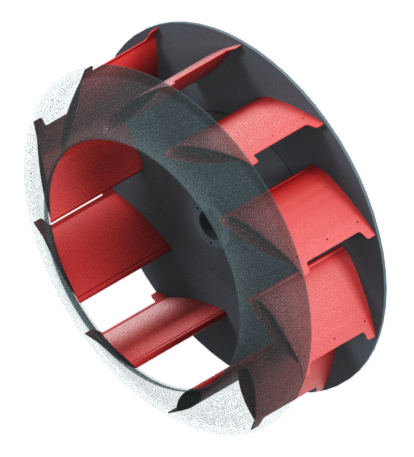

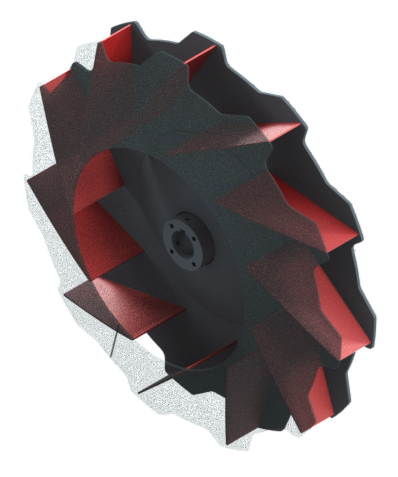

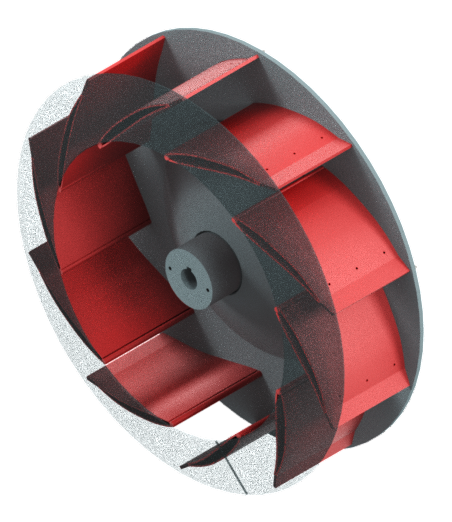

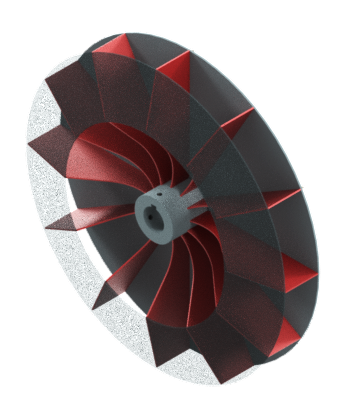

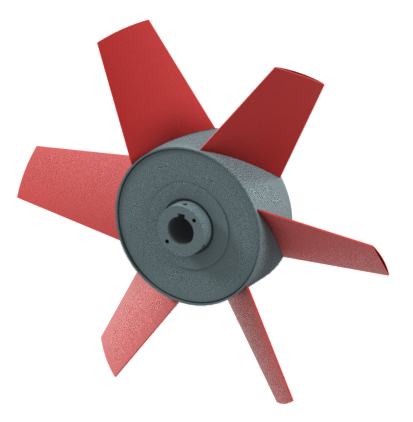

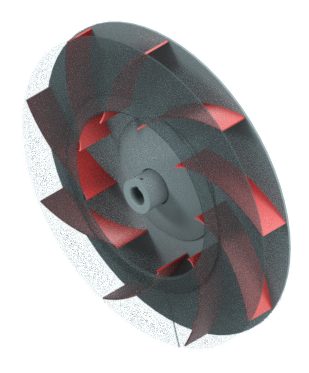

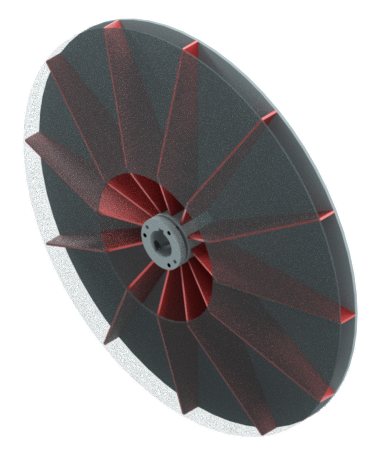

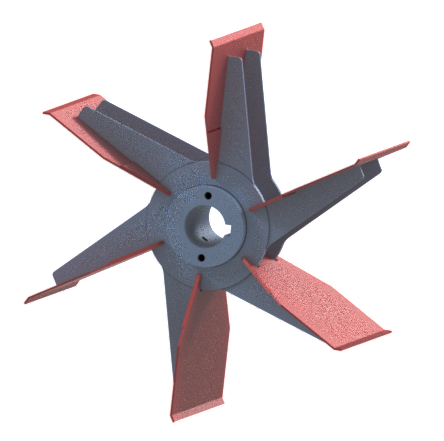

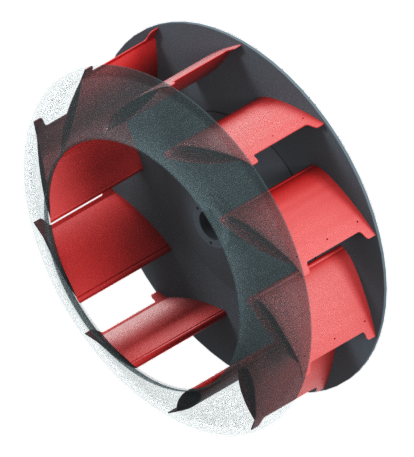

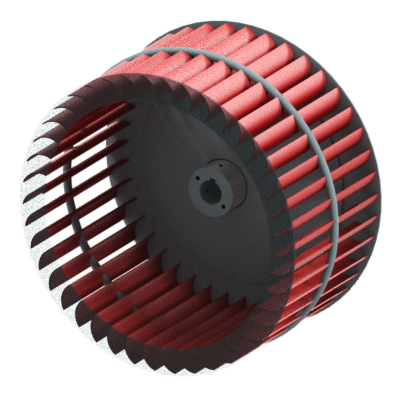

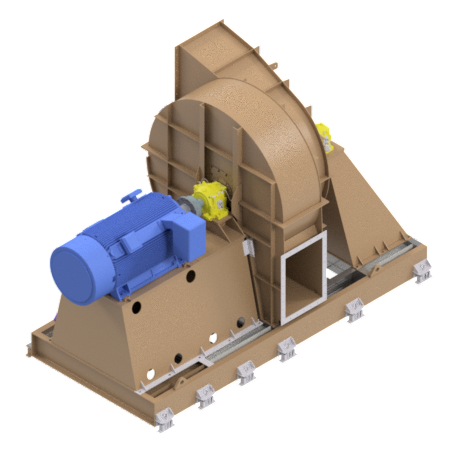

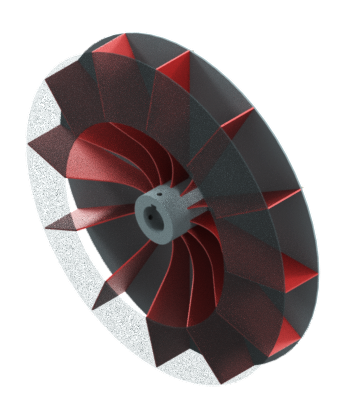

Radial Bladed Fan

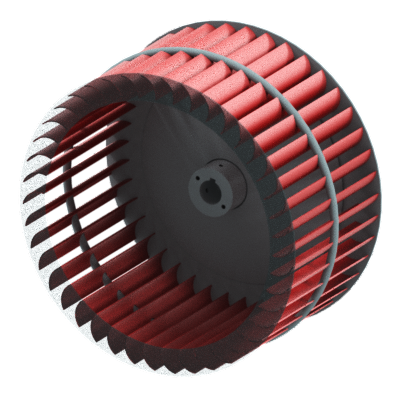

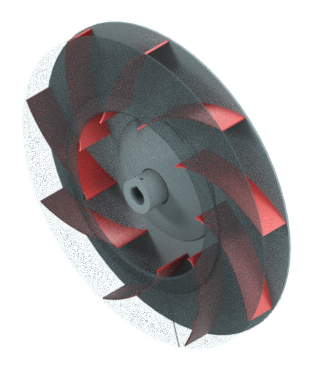

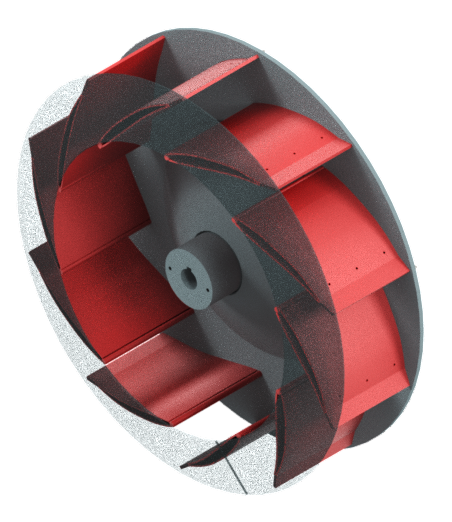

Types Of Fans

Used In Steel and Aluminum

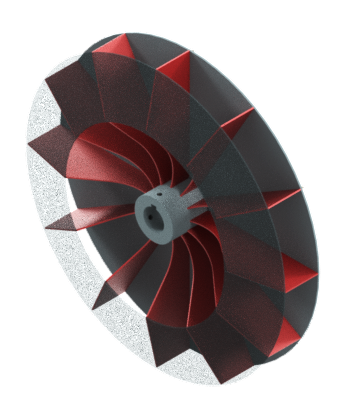

Centrifugal Fans

- Handle high temperatures, dust-laden air, and corrosive gases

- Used in combustion systems, exhaust/flue gas extraction, and pollution control units.

High-Temperature & Abrasion-Resistant Fans

- BMade with heat-resistant alloys, and abrasion resistant, reinforced blades to withstand extreme heat and wear.

Case Studies

Case Studies

Case Studies

Case Studies

Case Studies

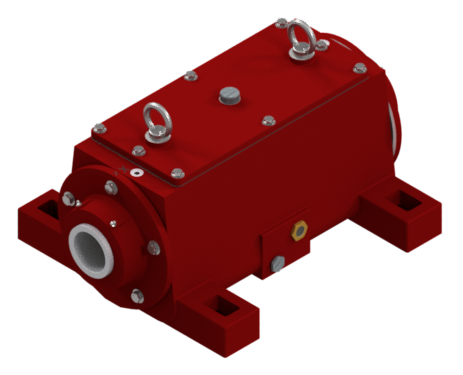

Industrial Fan Products

From replacement fan parts to complete custom-designed industrial fans, we have you covered.

Steel & Aluminum Industrial Fan Services

Robinson values our market-leading technical expertise as well as our outstanding customer service. We maintain these values in the services we offer to meet all of your industrial fan-related needs.

How

Can We

Help You?

How

Can We

Help You?

We work with

the biggest and best in the world

Why Robinson?

Over 130 years

of history

A sixth-generation

family-owned business,

Robinson offers unmatched

experience

Technical

Expertise &

Customization

standard fan lines, Robinson

customizes every solution to

meet specific customer needs

Top Notch

Customer Service

quality and long-term

relationships

Rapid

Response 24/7

24/7 emergency breakdown

services and a dedicated

Rapid Repair team for a quick turnaround