Biomass Fuel & Ethanol

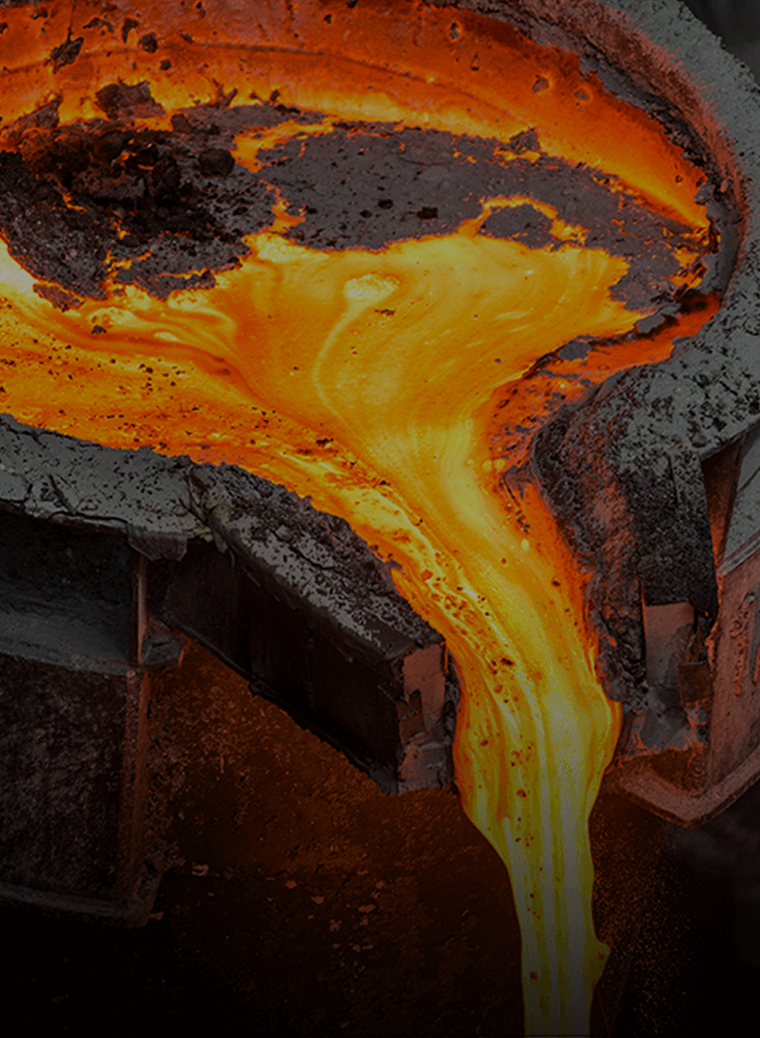

Biomass is a drenewable organic material that can be burned directly for heat or converted to liquid and gaseous fuels through various processes. Biomass was the largest source of total annual U.S. energy consumption until the mid-1800s. Currently, biomass accounts for ~5% of U.S. total primary energy consumption. Biomass is used for heating and electricity generation as well as transportation fuel.

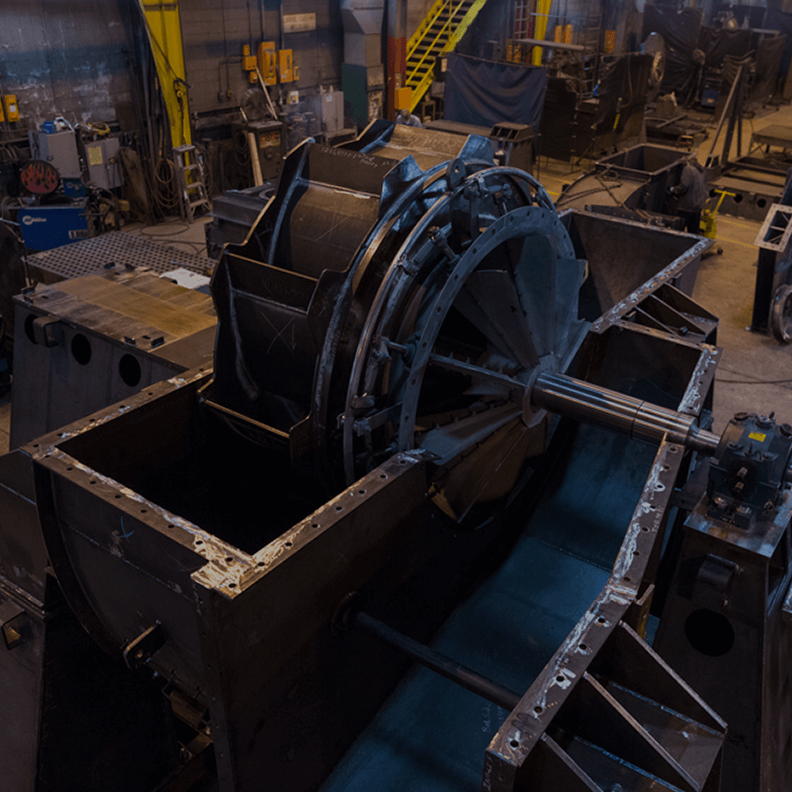

Biofuel processing is intensive, both from a capital cost and high-energy requirement. Throughout the process lifecycle, from drying to fermentation, separation, and energy recovery, Robinson fans play a role.

Applications

Combustion Air Supply

- In biofuel plants, industrial fans provide combustion air to boilers and furnaces, enhancing combustion efficiency.

- Proper airflow ensures complete combustion, reducing unburned fuel and emissions.

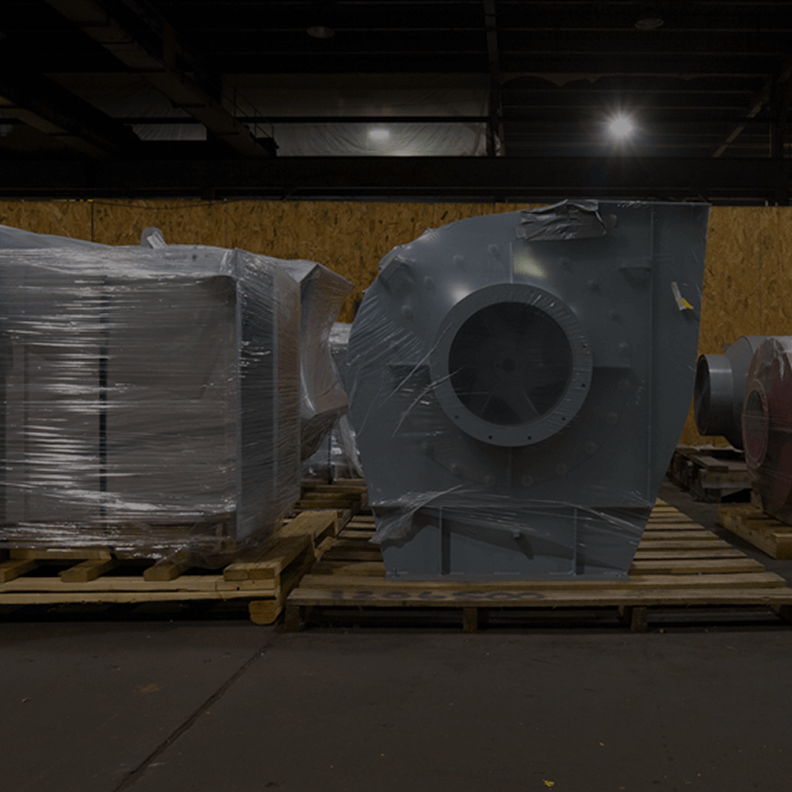

Drying & Material Handling

- High-temperature fans assist in drying systems by circulating hot air through rotary dryers or ring-dryers.

- Pneumatic conveying fans help transport biomass materials between processing stages.

Dust Control and Air Filtration

- Biomass processing generates significant dust and particulate matter.

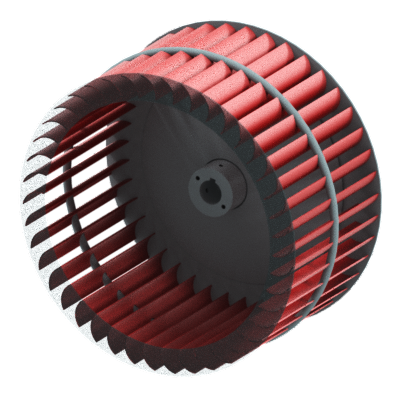

- Centrifugal and baghouse fans are used in dust collection systems to maintain clean and safe air quality.

Emissions Control

- Ethanol and biomass fuel plants use scrubbers, baghouses, cyclones, and electrostatic precipitators to reduce pollutants.

- Fans draw gases through pollution control equipment like thermal oxidizers (RTOs), ensuring compliance with environmental regulations.

Ethanol and Biofuel Fan Repair

Is your fan broken or needs repair ASAP!? Contact us now for 24/7 emergency fan service.

Ethanol and Biofuels

Fan Design

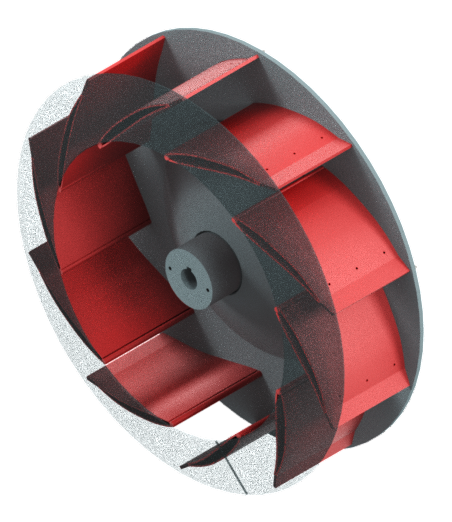

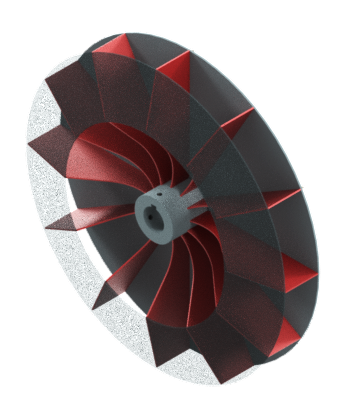

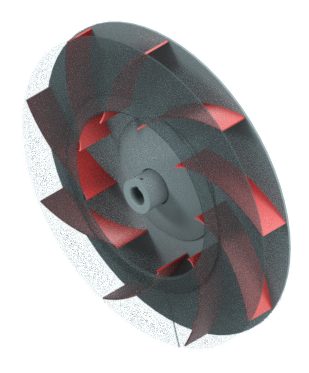

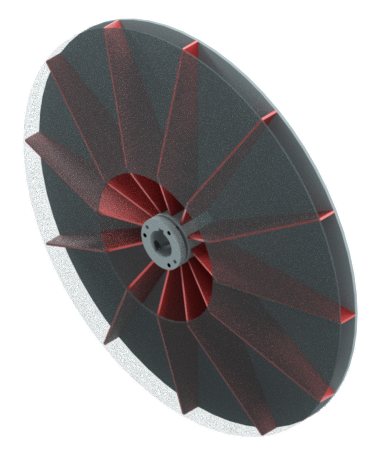

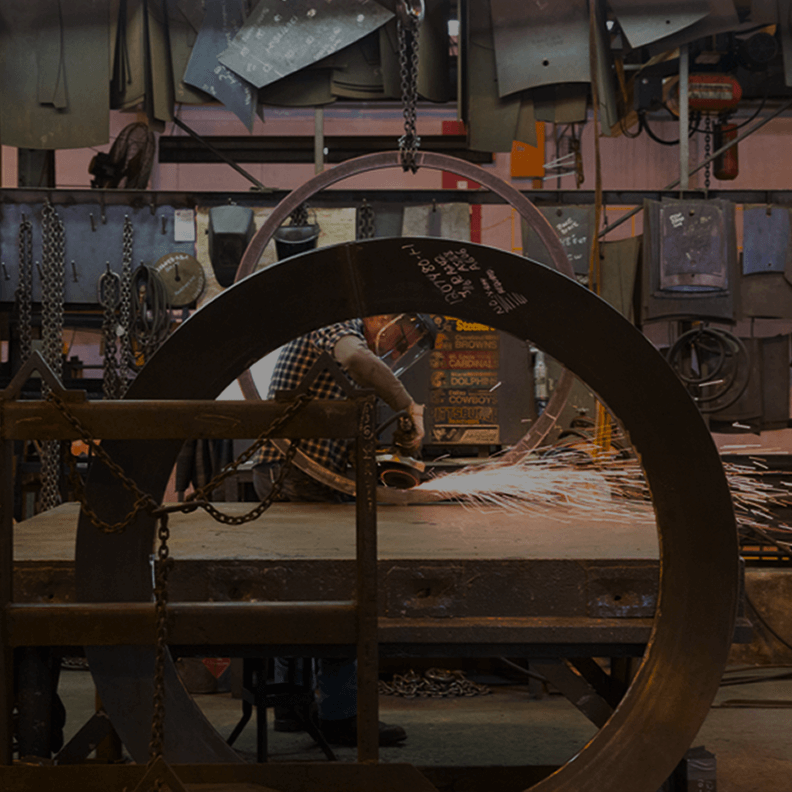

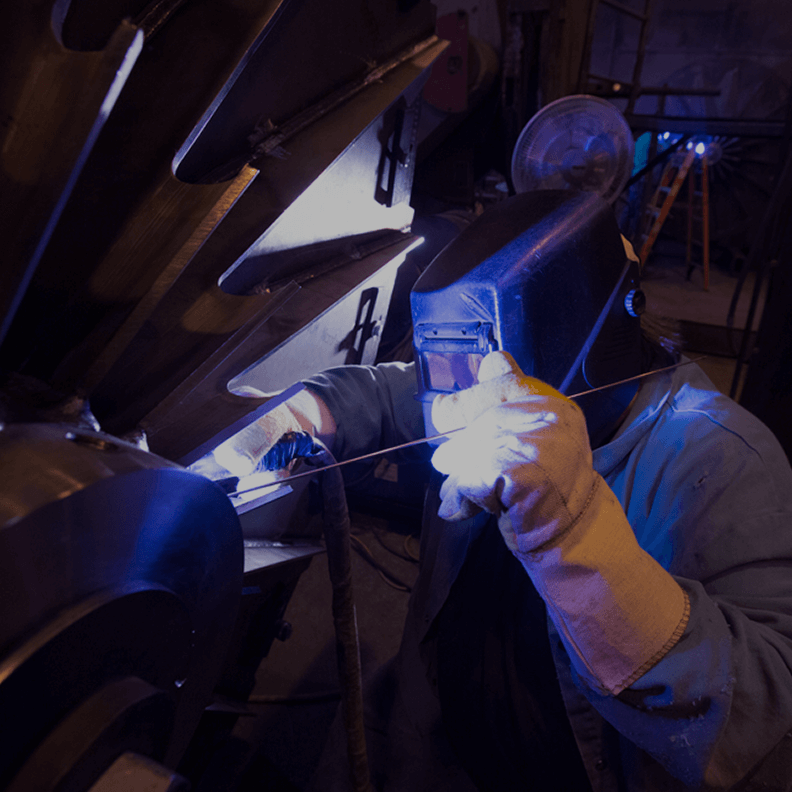

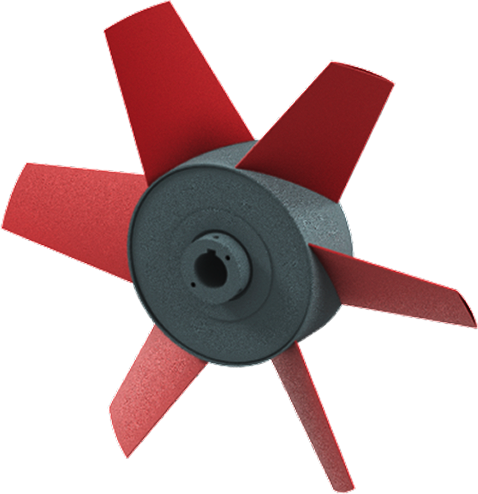

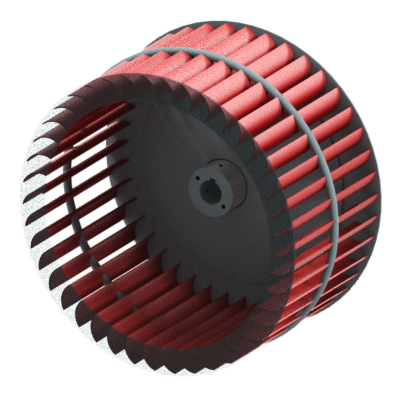

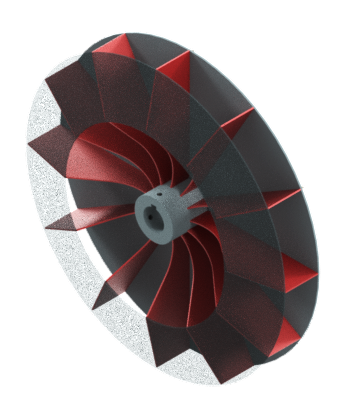

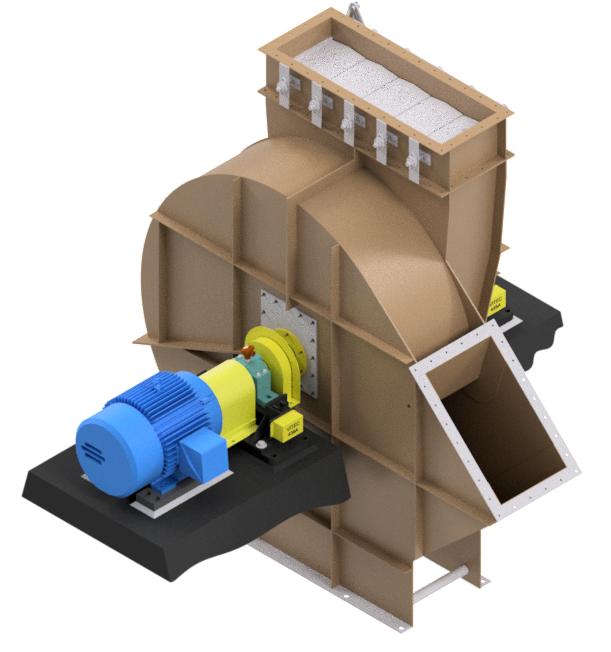

The biofuel and ethanol industry requires process fans for several different applications. Robinson Fans has been supplying equipment for these facilities since the start of the industry and has a proven track record of equipment reliability. We provide custom-engineered fan equipment for drying systems, oxidizers (RTO), fired heaters, as well as other applications.

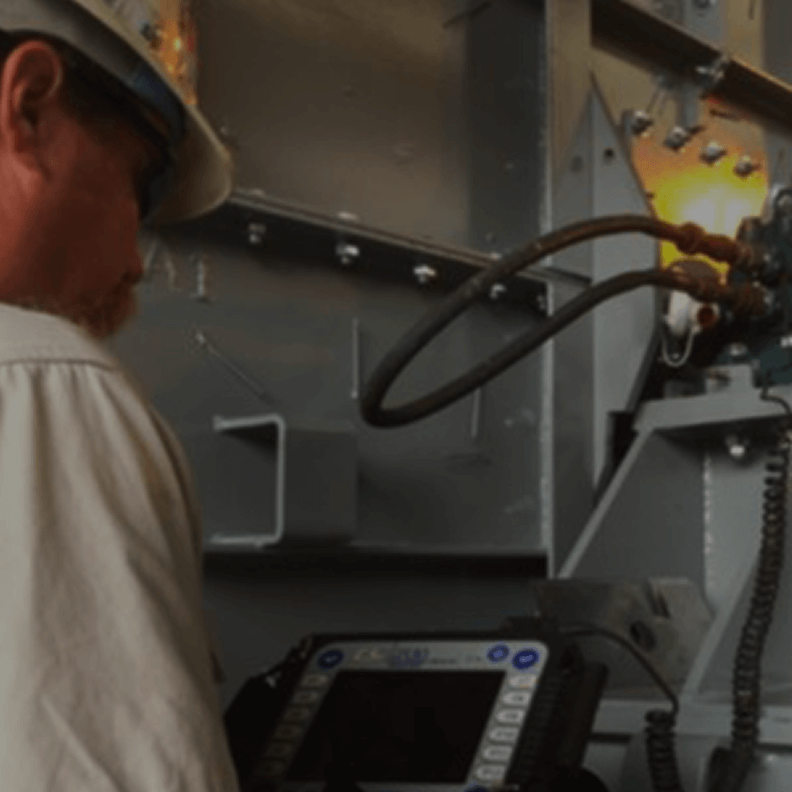

Fan Inspection and Repair

Fans and other equipment in biofuel and ethanol facilities can be subject to corrosion due to condensation of acids within the gas stream. Robinson designs fan equipment with specific materials to reduce corrosion, but some equipment may not have this upgrade. Regular inspections of the fan internal components is recommended.

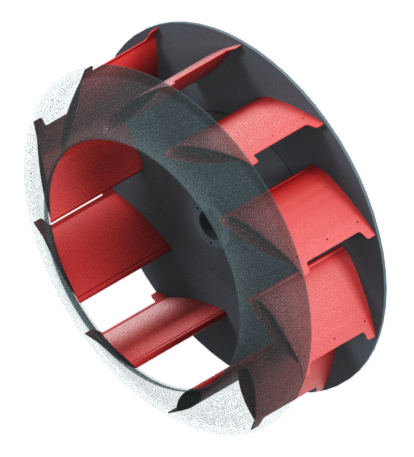

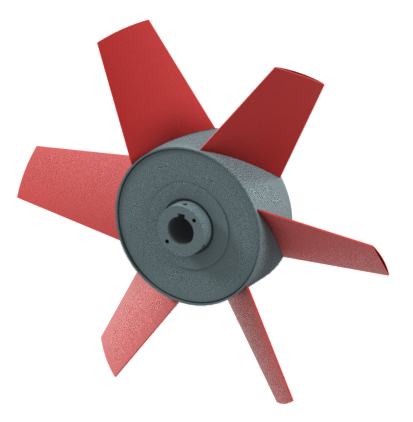

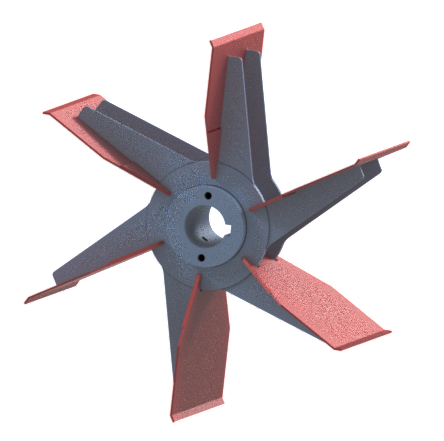

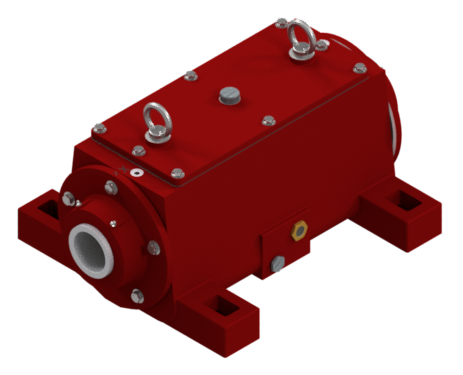

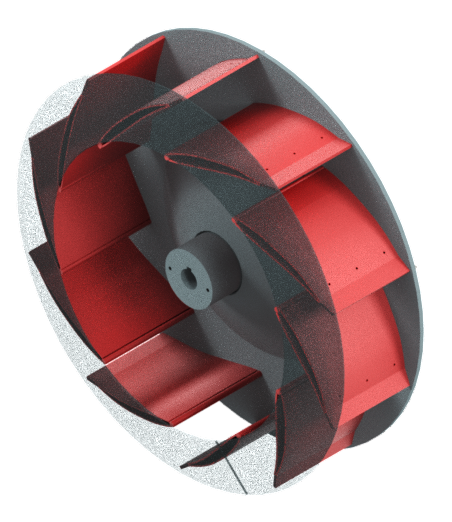

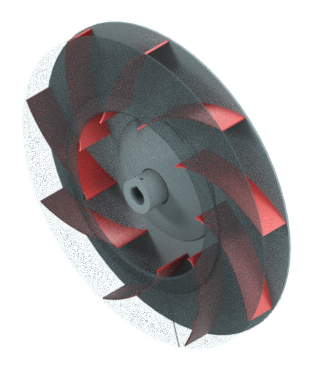

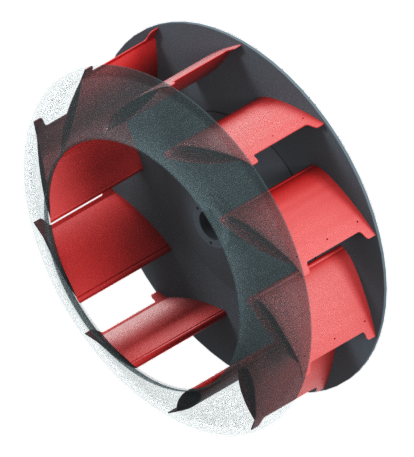

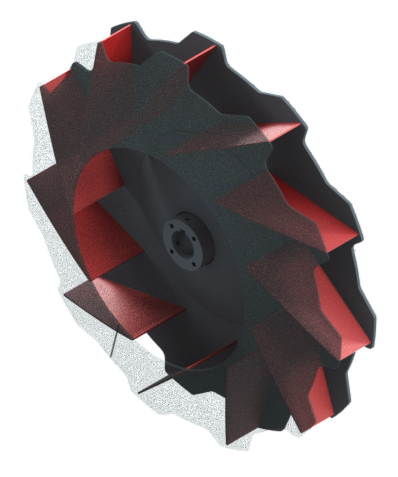

Backward Inclined Fans

Key Design Considerations

Airflow and Pressure Requirements

- Fans must deliver the correct airflow and static pressure for the defined gas stream conditions (Temperature, molecular weight, elevation, etc.).

Temperature Resistance

- Biomass combustion systems and ethanol distillation generate high temperatures.

- Fans must be designed with the proper materials for the design temperatures and induced stresses.

Material Durability & Corrosion Resistance

- Biofuel and ethanol production create corrosive environments due to moisture, chemicals, and acidic byproducts.

- Fans in ethanol plants may require corrosion-resistant materials.

Dust and Particulate Handling

- Biomass processing produces dust and particulates that can erode fan components.

- Abrasion-resistant materials (e.g., AR steel, chrome carbide, etc.) help improve fan life and reduce downtime.

- Proper dust collection and filtration systems must be integrated to prevent dust buildup and fire hazards.

Energy Efficiency

- Fans consume significant energy, so premium-efficiency motors and variable frequency drives (VFDs) can help reduce power consumption.

- Optimized impeller design improves aerodynamic performance, lowering operational costs.

Explosion & Fire Safety

- Ethanol production involves flammable vapors, requiring explosion-proof fans in certain areas.

- Spark-resistant construction (e.g., aluminum or low-iron materials) reduces ignition risks.

Noise & Vibration Control

- Fans can generate excessive noise and vibration, reducing reliability, if not properly designed.

- Acoustic insulation and silencers can be used to reduce noise levels.

- Fans are dynamically balanced to prevent high vibration at start-up and operation.

Maintenance and Reliability

- Fans should be designed for the specific application for ease of maintenance and reliability.

- Properly located inspection doors and removable housing sections for cleaning, easy rotor change out, etc.

Industrial Fan Products

From replacement fan parts to complete custom-designed industrial fans, we have you covered.

Ethanol & Biofuel Fan Services

Robinson values our market-leading technical expertise as well as our outstanding customer service. We maintain these values in the services we offer to meet all of your industrial fan-related needs.

How

Can We

Help You?

How

Can We

Help You?

We work with

the biggest and best in the world

Why Robinson?

Over 130 years

of history

A sixth-generation

family-owned business,

Robinson offers unmatched

experience

Technical

Expertise &

Customization

standard fan lines, Robinson

customizes every solution to

meet specific customer needs

Top Notch

Customer Service

quality and long-term

relationships

Rapid

Response 24/7

24/7 emergency breakdown

services and a dedicated

Rapid Repair team for a quick turnaround