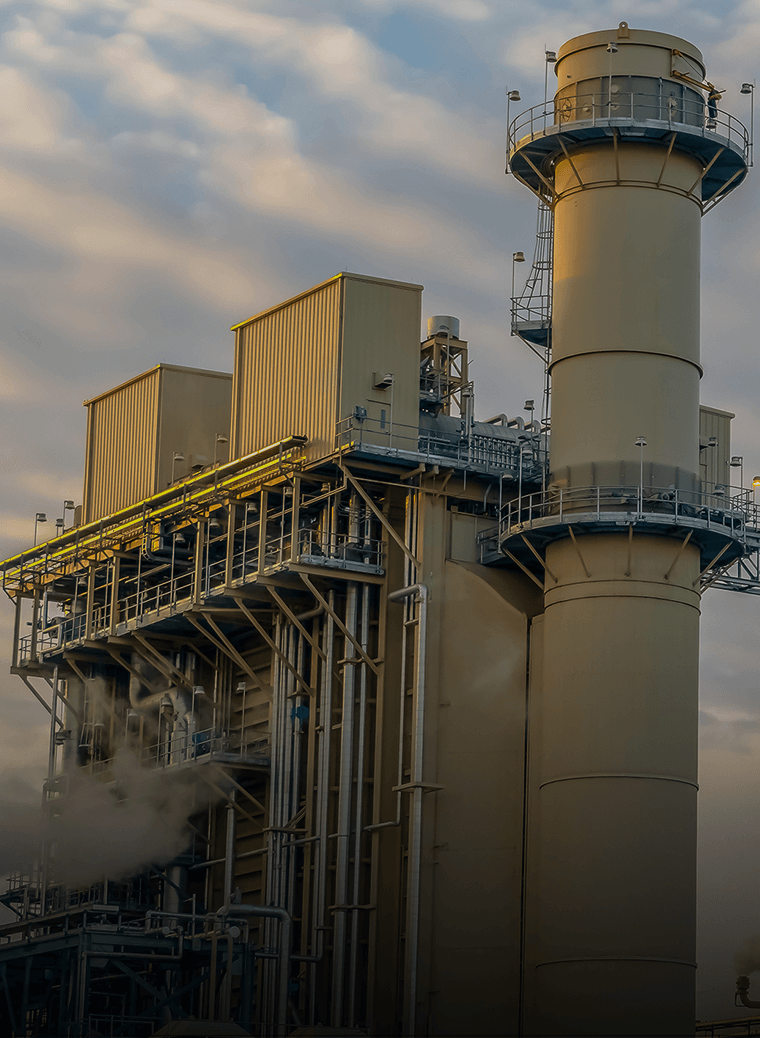

chemical & petrochemical

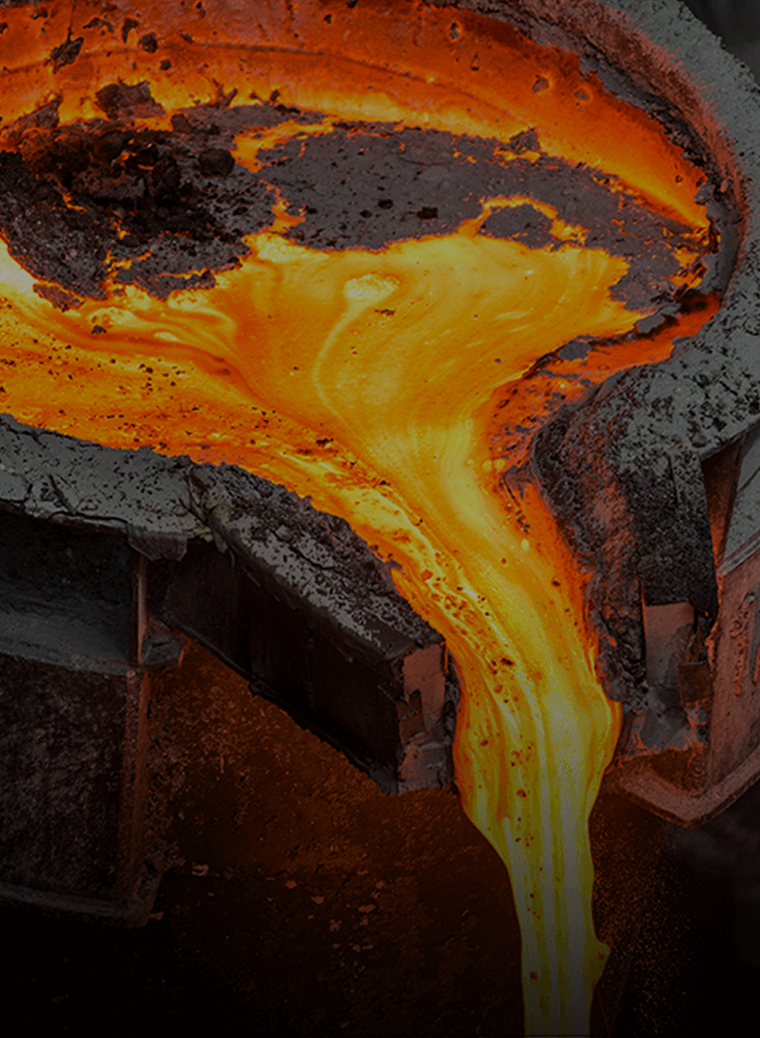

The chemical and petrochemical industry is a global sector that produces essential raw materials and products used in manufacturing, agriculture, healthcare, and consumer goods. It plays a critical role in modern economies by transforming raw materials such as crude oil, natural gas, minerals, and biomass into valuable chemicals, polymers, and fuels.

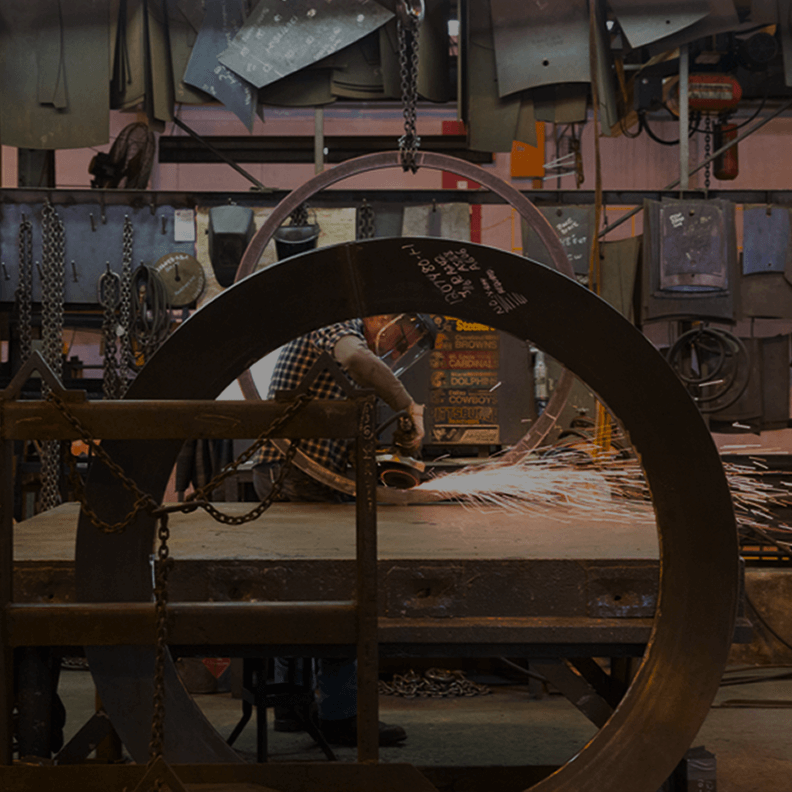

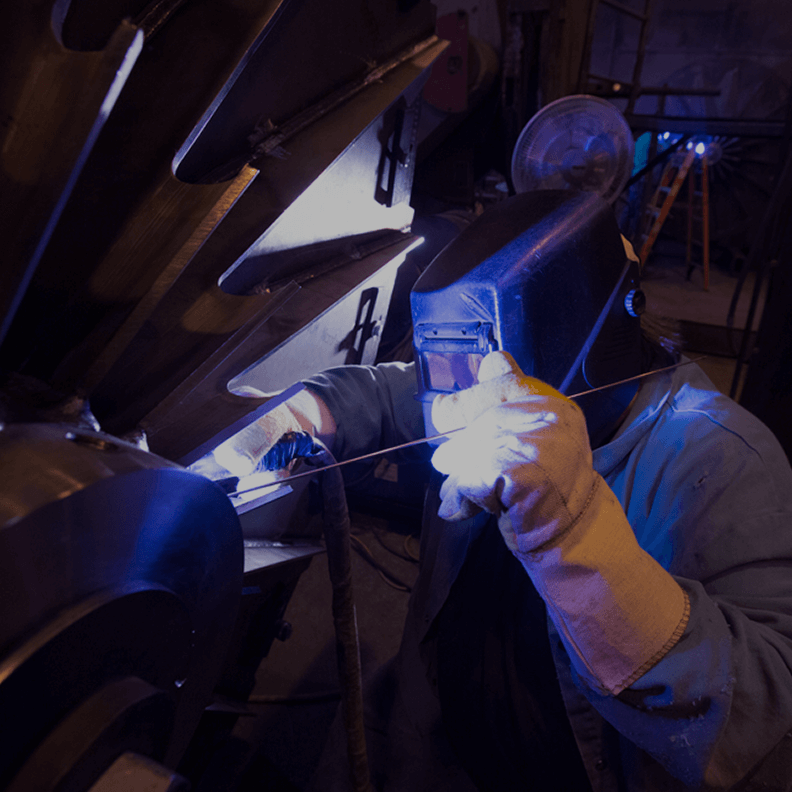

Industrial fans are a critical component in the chemical and petrochemical industry. A few examples would be fired-heater systems, reactors, and emissions control. These fans may need to comply with API (American Petroleum Institute) standards like API 673, API560, etc. Robinson is an industry leader in the engineering, design, and construction of API compliant fans.

Applications

Combustion Air & Exhaust Systems

- Supplies combustion air to boilers, furnaces, and reactors.

- Remove combustion byproducts and volatile organic compounds (VOCs).

Filtration & Pollution Control

- Fans are integrated into scrubbers, baghouses, and electrostatic precipitators to control emissions.

- Helps comply with environmental regulations on air quality and hazardous emissions.

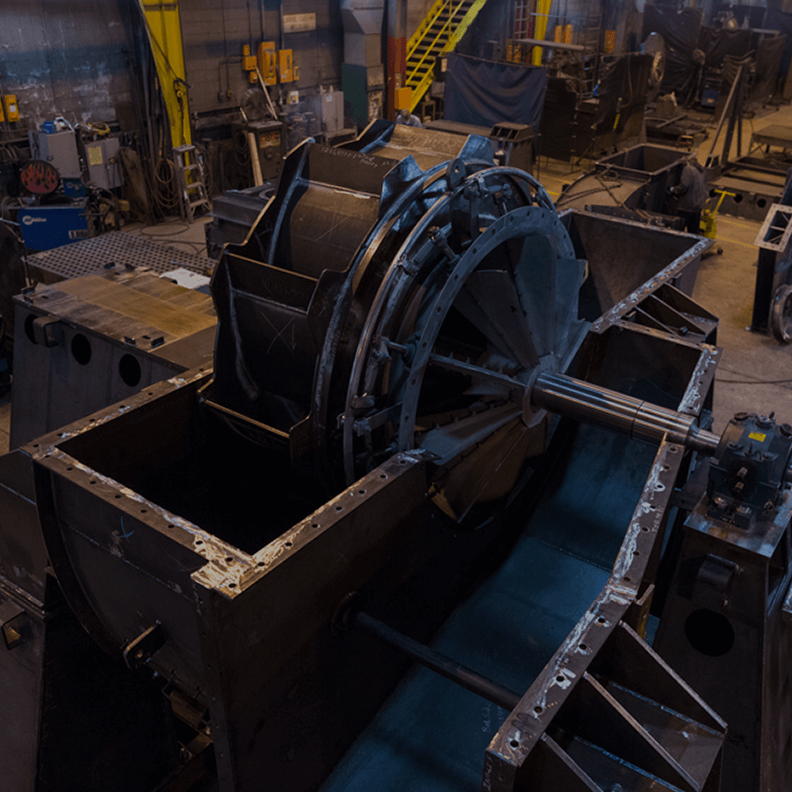

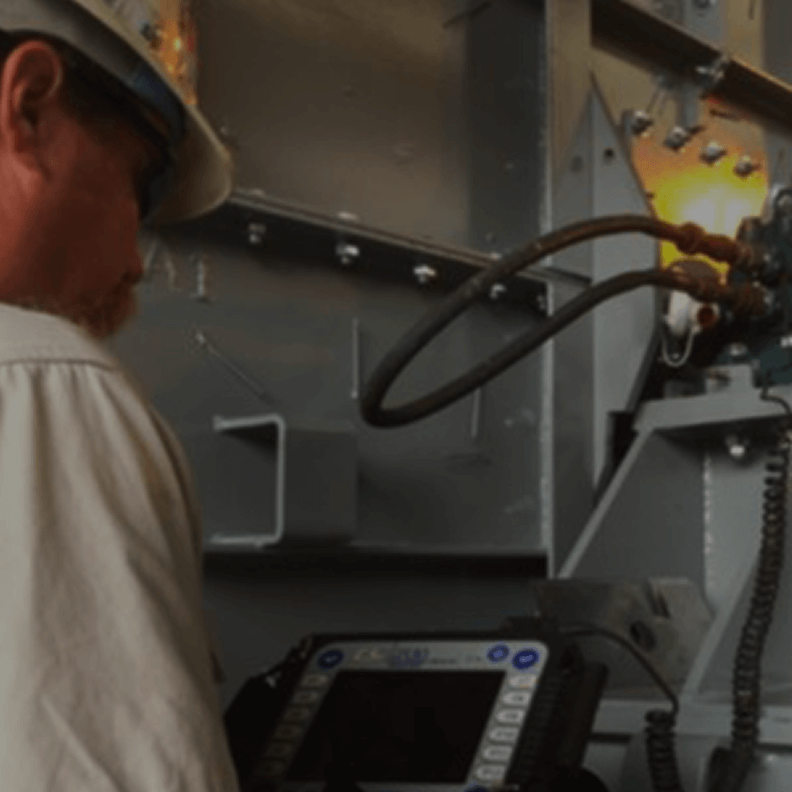

Chemical and Petrochemical Emergency Fan Repair

Unplanned downtime is a nightmare. Robinson combines world-class technical expertise with outstanding customer service to minimize downtime and cost. Our aim is to provide the best quality product to ensure your facility is operating as soon as possible.

Chemical & Petrochemical

Fan Design

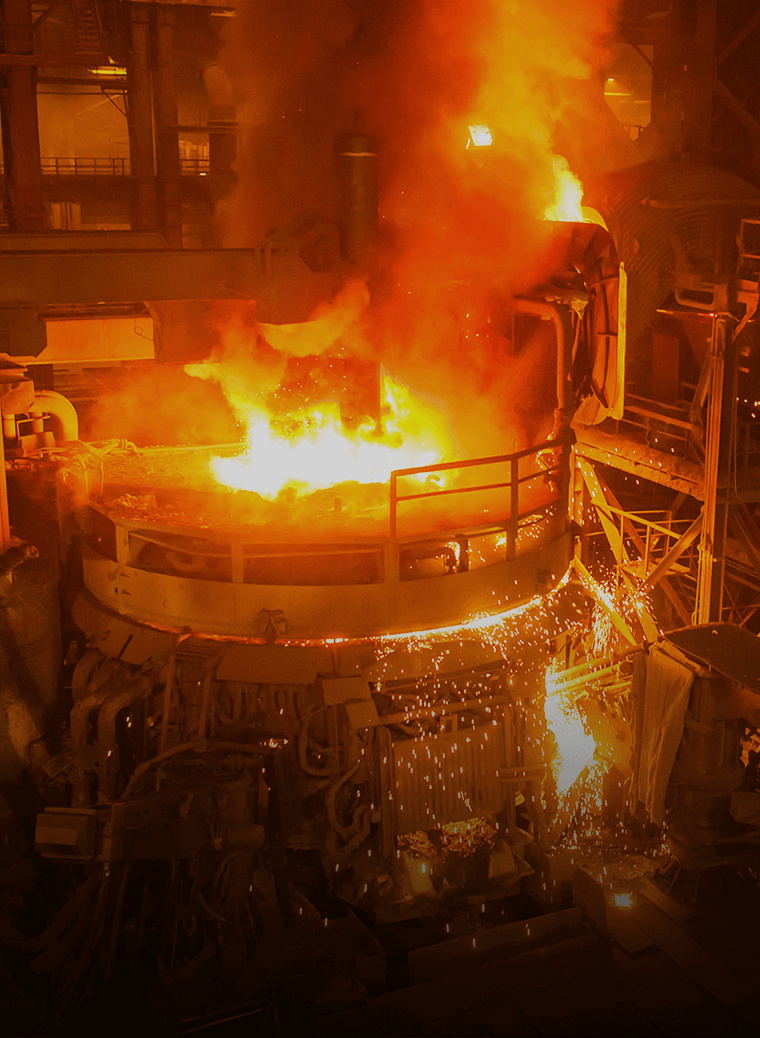

Due to the harsh environments in the chemical and petrochemical industries, fans must be designed with:

Corrosion & Chemical Resistance

- Materials: Stainless steel, aluminum, fiberglass-reinforced plastic (FRP), and special coatings.

- Protects against acids, alkalis, and aggressive gases like hydrogen sulfide (H2S).

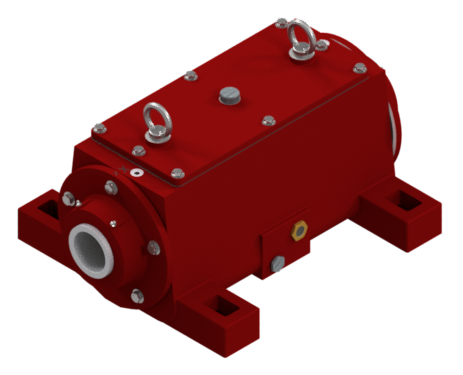

Explosion-Proof & ATEX Compliance

- Hazardous Locations: Many processes involve flammable gases and dust.

- Fans may need to meet ATEX (EU) or NFPA.

Temperature Considerations

- High-temperature materials and cooling mechanisms are required for high-temperature processes.

Energy Efficiency & Control

- Variable Frequency Drives (VFDs) optimize airflow and reduce power consumption at turndown and start-up conditions.

- Industrial Dampers provide proper fan control to hit multiple operational points including turndown and start-up conditions.

Chemical & Petrochemical

Fan repair

Are you seeing corrosion or wear and tear due to chemical exposure and/or high temperatures? Are you concerned about the fan performance given the energy-intensive operations that are required?

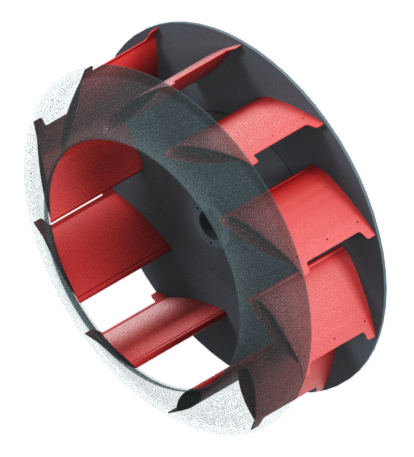

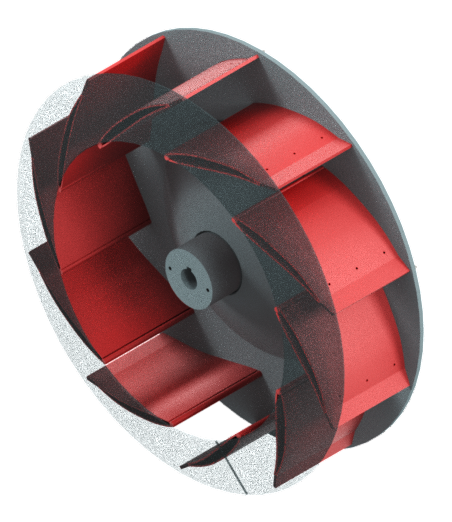

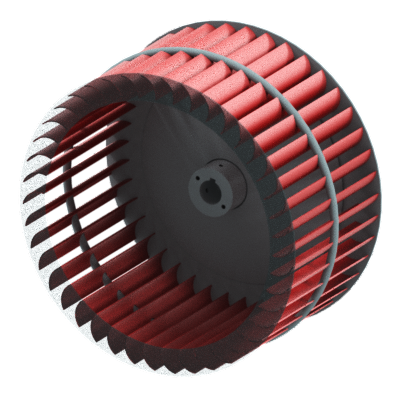

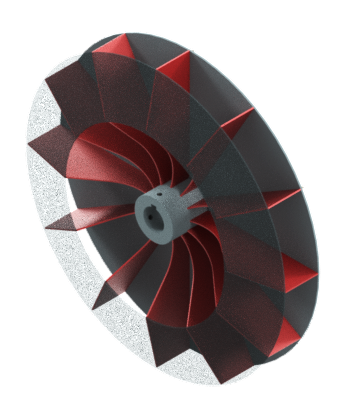

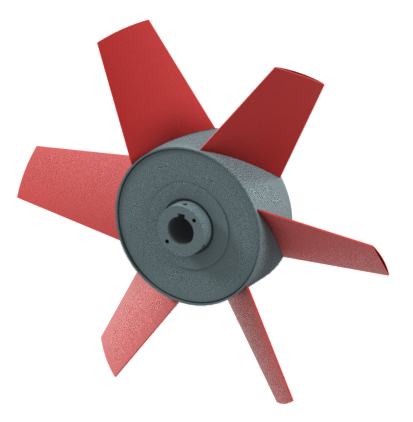

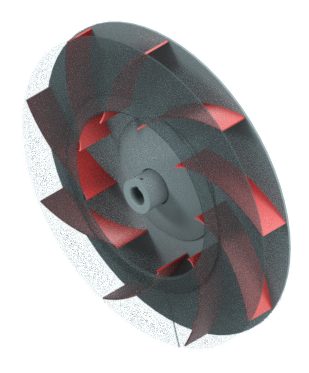

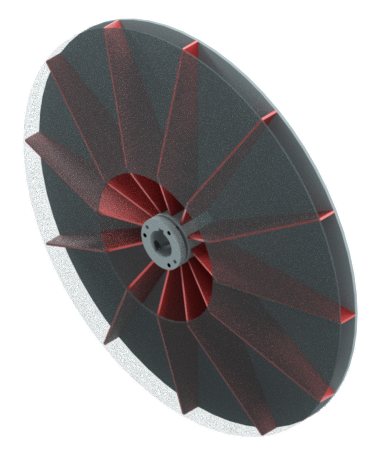

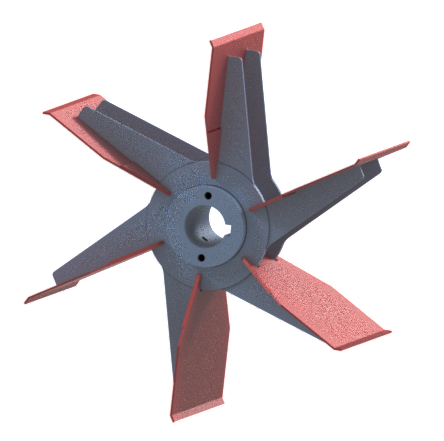

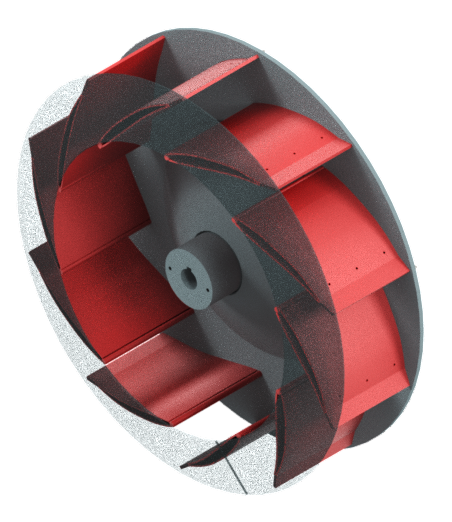

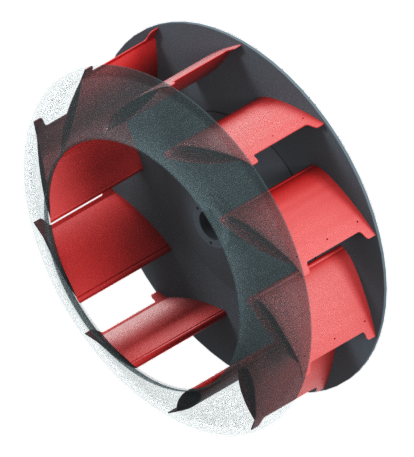

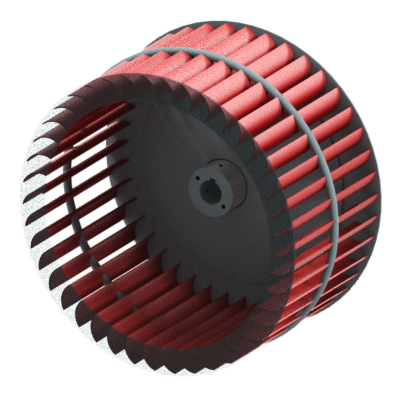

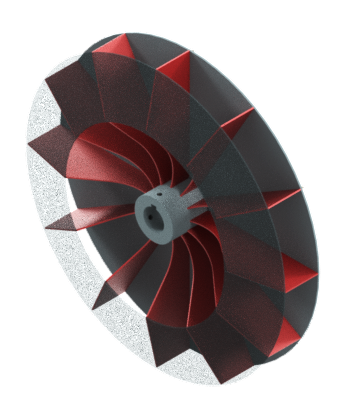

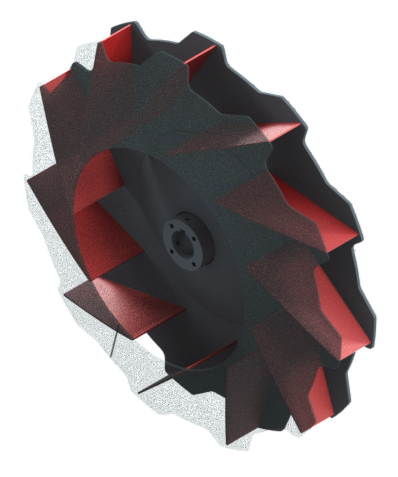

Backward Inclined Fans

Types Of Fans

Used In Chemical & Petrochemical

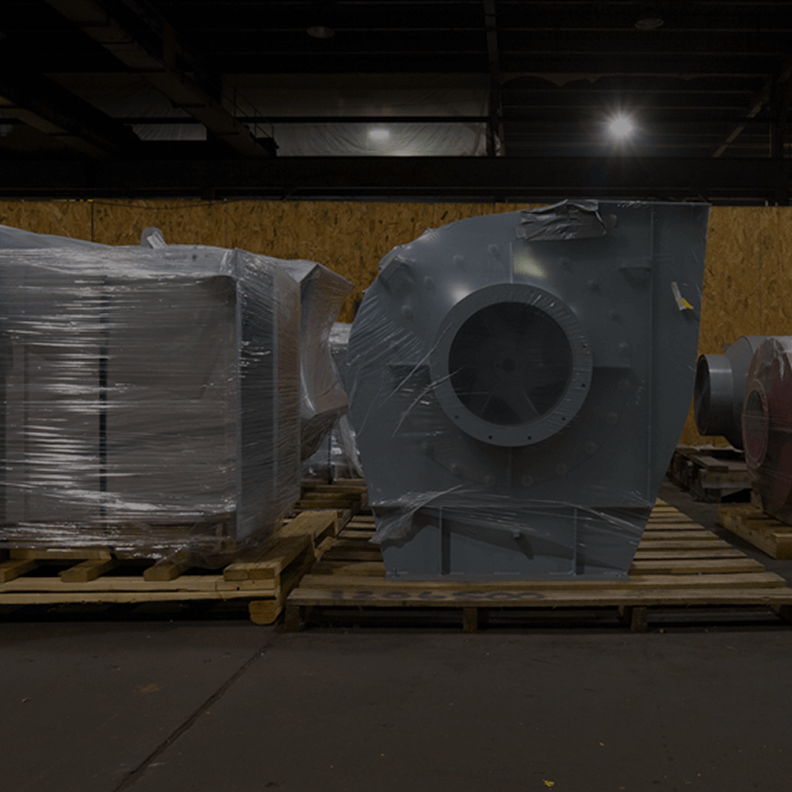

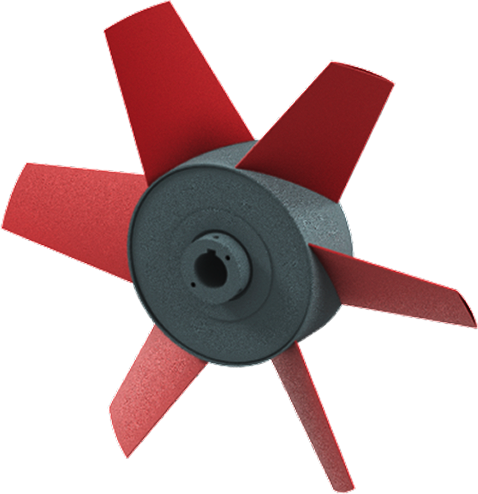

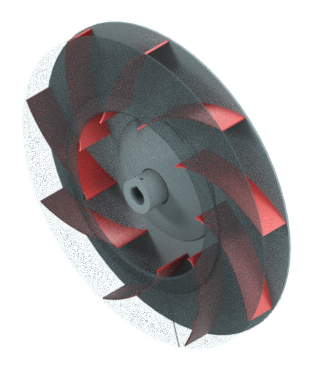

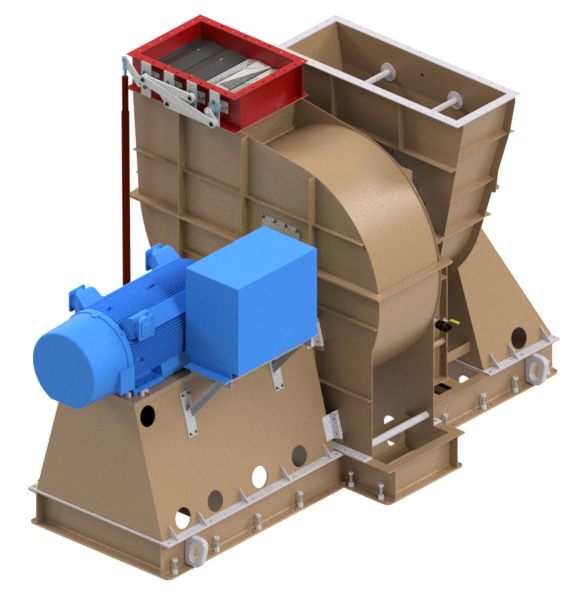

Centrifugal Fans

- Provide airflow required in emissions control, combustion heating, and exhaust applications.

- Common designs include airfoil, backward inclined, and backward-curved.

High-Temperature & Corrosion-Resistant Fans

- Designed for extreme heat, corrosive gases, and hazardous environments.

- Materials: Stainless steel, fiberglass-reinforced plastic (FRP), and other alloy materials.

Industrial Fan Products

From replacement fan parts to complete custom-designed industrial fans, we have you covered.

Chemical & Petrochemical Fan Services

Robinson values our market-leading technical expertise as well as our outstanding customer service. We maintain these values in the services we offer to meet all of your industrial fan-related needs.

How

Can We

Help You?

How

Can We

Help You?

We work with

the biggest and best in the world

Why Robinson?

Over 130 years

of history

A sixth-generation

family-owned business,

Robinson offers unmatched

experience

Technical

Expertise &

Customization

standard fan lines, Robinson

customizes every solution to

meet specific customer needs

Top Notch

Customer Service

quality and long-term

relationships

Rapid

Response 24/7

24/7 emergency breakdown

services and a dedicated

Rapid Repair team for a quick turnaround