A

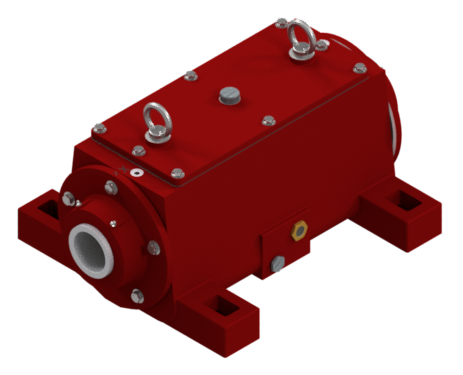

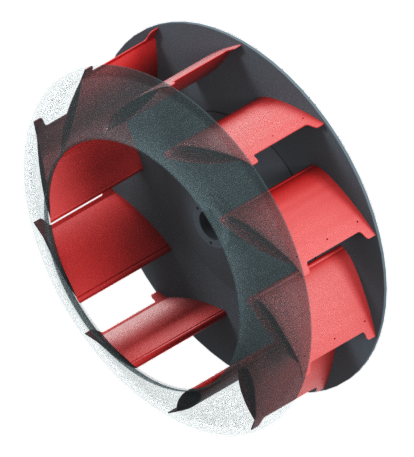

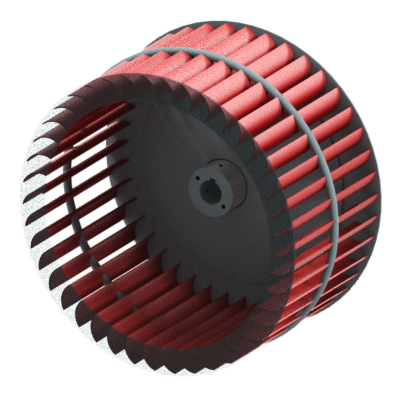

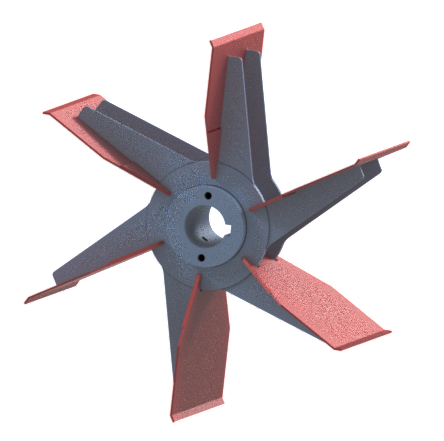

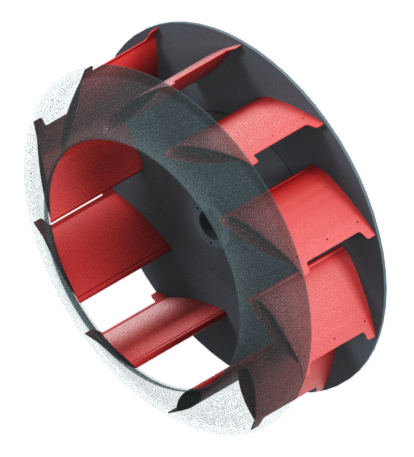

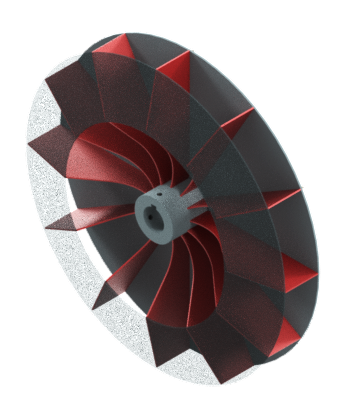

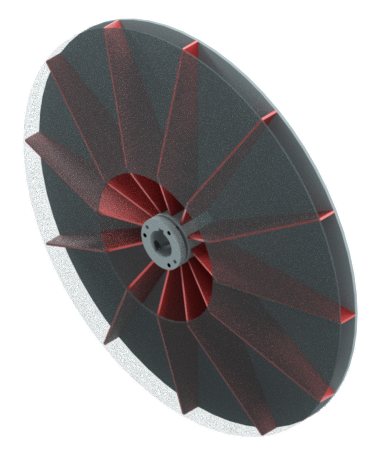

bout RobinsonRobinson maintains its 130+ year reputation as a market-leading, industrial fan manufacturer founded on world-class technical expertise and outstanding customer service. Now in its sixth-generation of family business ownership, it is looking toward its future growth; building on a strong brand reputation of innovation and quality to deliver the best air moving equipment to its customers.

Our Vision

To be the leading manufacturer of high-quality, innovative air-movement solutions, creating a better future for our family and yours.

History

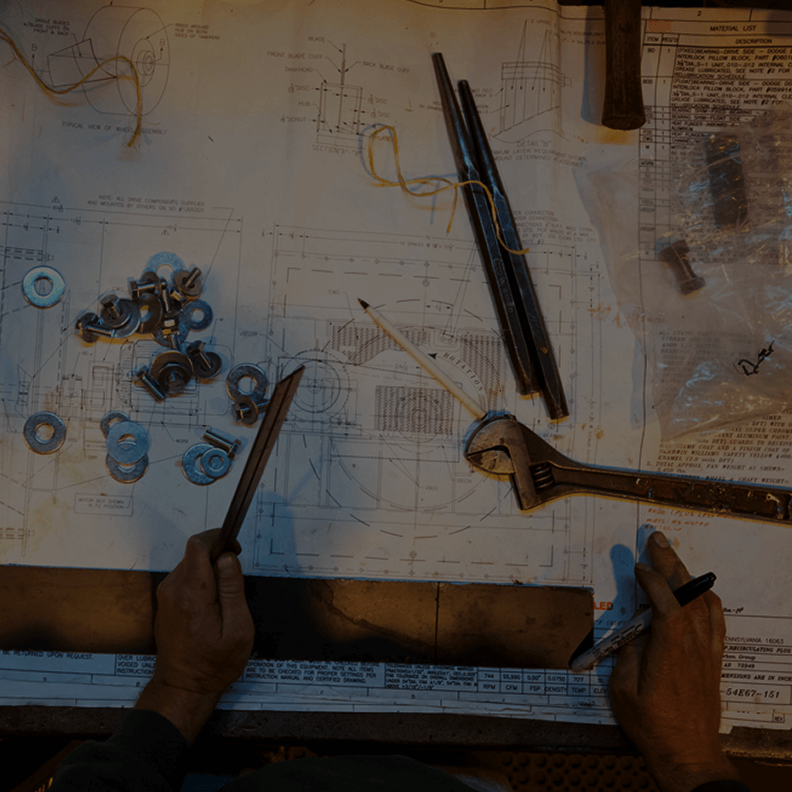

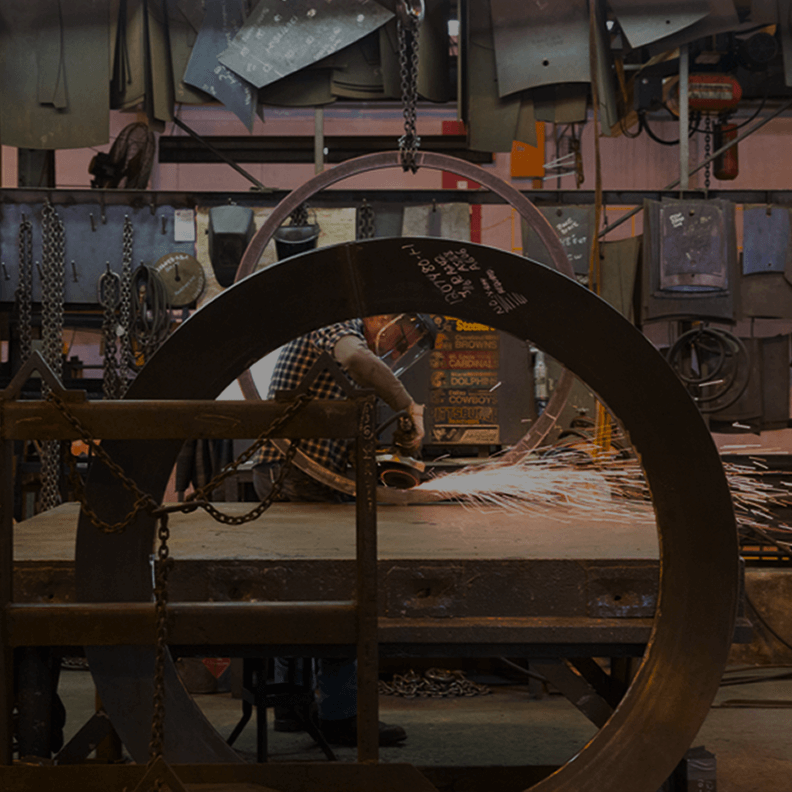

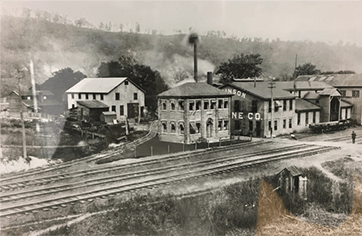

The story of Robinson begins in 1892, when Samuel and his son, J.R. Robinson acquired a machine company in Monongahela, PA and established the Robinson Machine Company to provide technically superior equipment and customer service to the coal industry. J.R. served as Chief Engineer developing a complete line of equipment, including: fans, steam boilers, engines, hoists, crushers, and haulers for coal mines and mills. It was J.R.’s work that laid the foundation for the future success of Robinson Fans, Inc.

In 1907, Robinson Machine Company became Robinson Ventilating Company specializing in mine ventilation. In 1921, Robinson moved its facilities to Zelienople, PA, which remains as a flagship location for the business today.

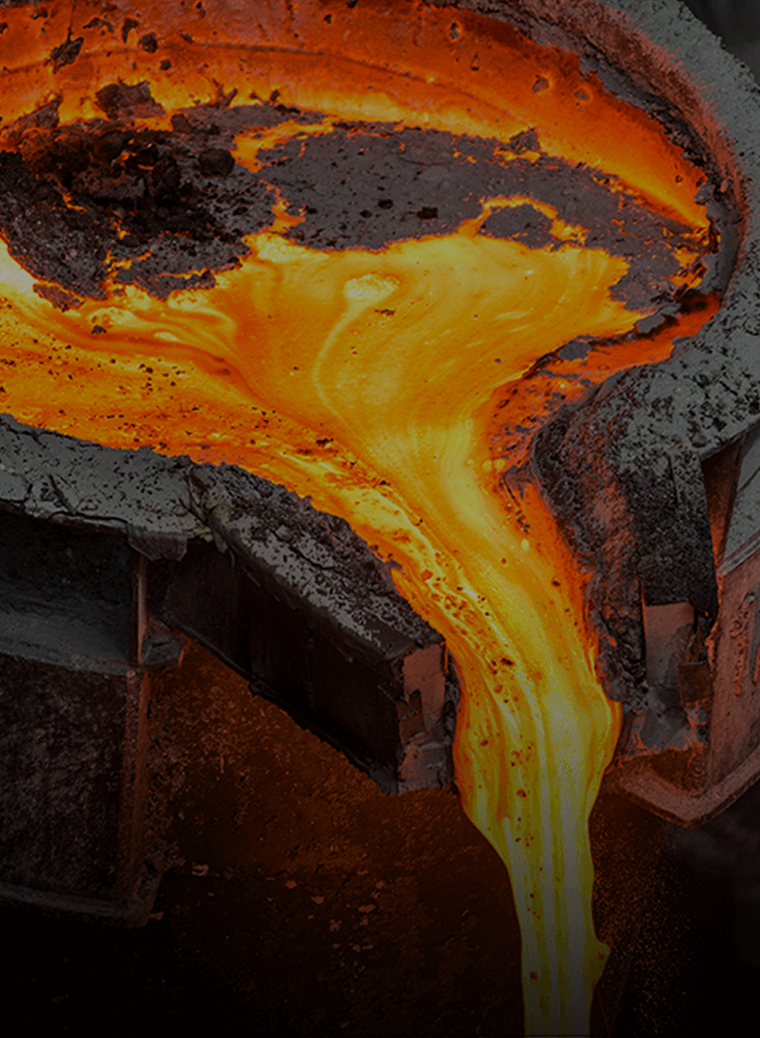

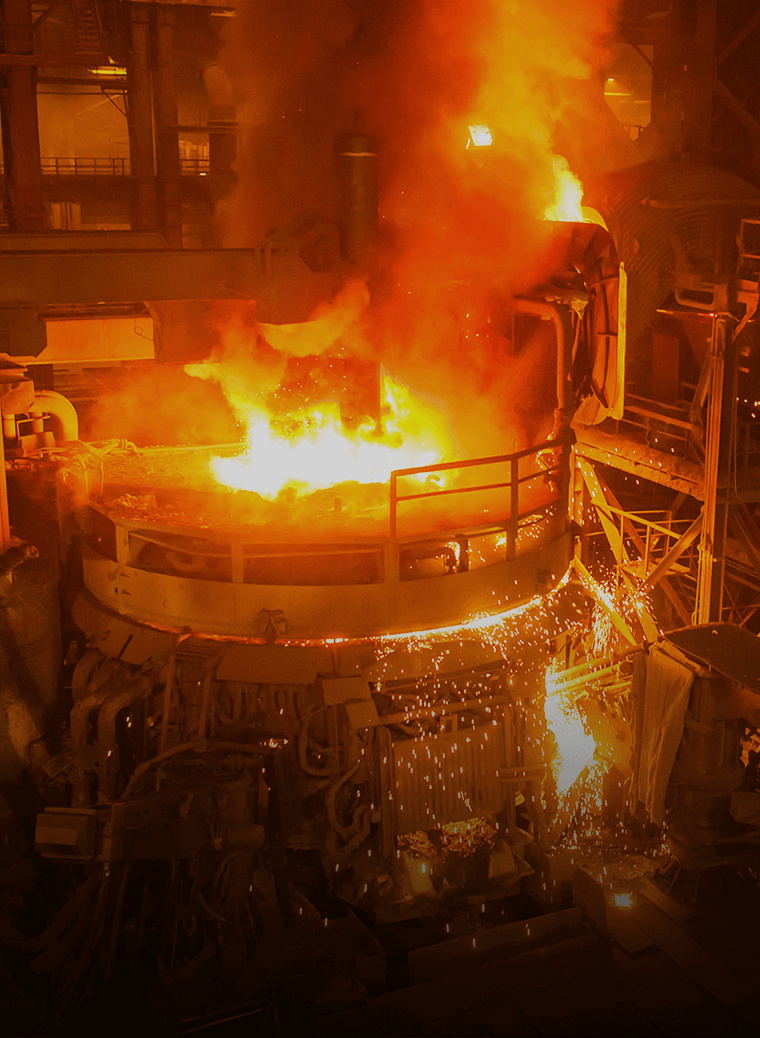

Sustainability has always been core to the Robinson history. As the coal industry evolved and the applications for industrial ventilation grew, so did Robinson. In the 1930s, J.R. pioneered research in coal-drying and heat-treatment processes for the steel industry, which led Robinson to develop high-temperature fan equipment. Twenty years later, controlled drying methods to dry crops such as corn and hay were being developed. Robinson expanded its customer base to include the fertilizer industry and subsequently the pollution control market in the 1970s. To meet the growing demand, Robinson Fans opened its second location in Lakeland, Florida in 1976.

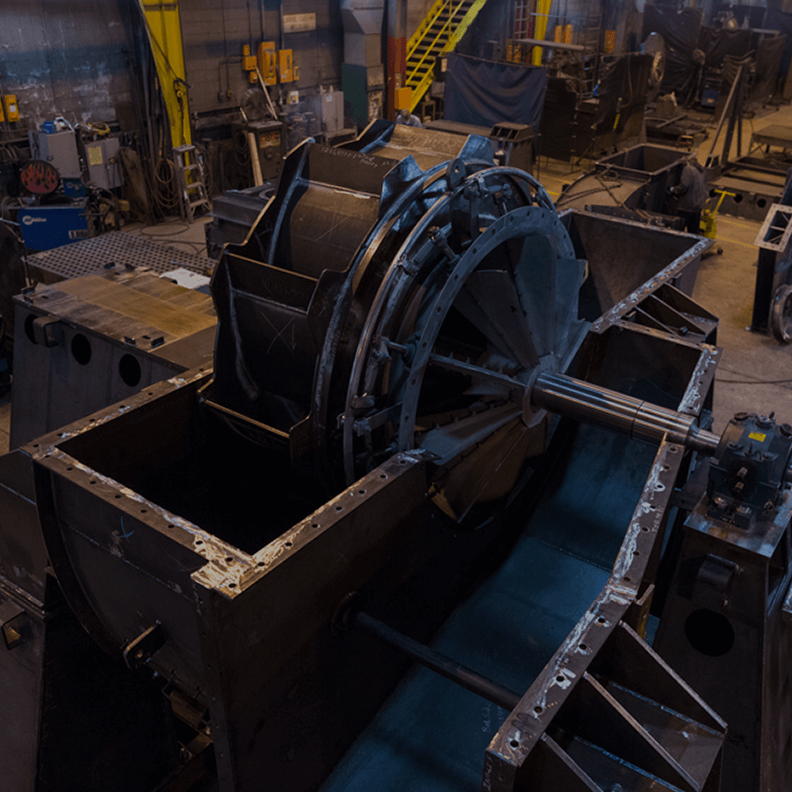

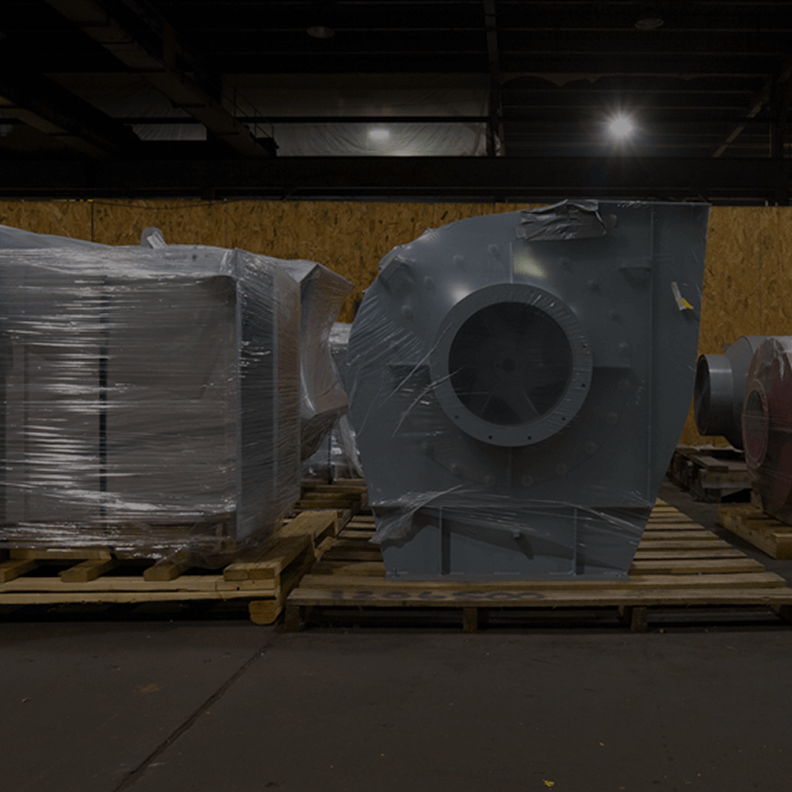

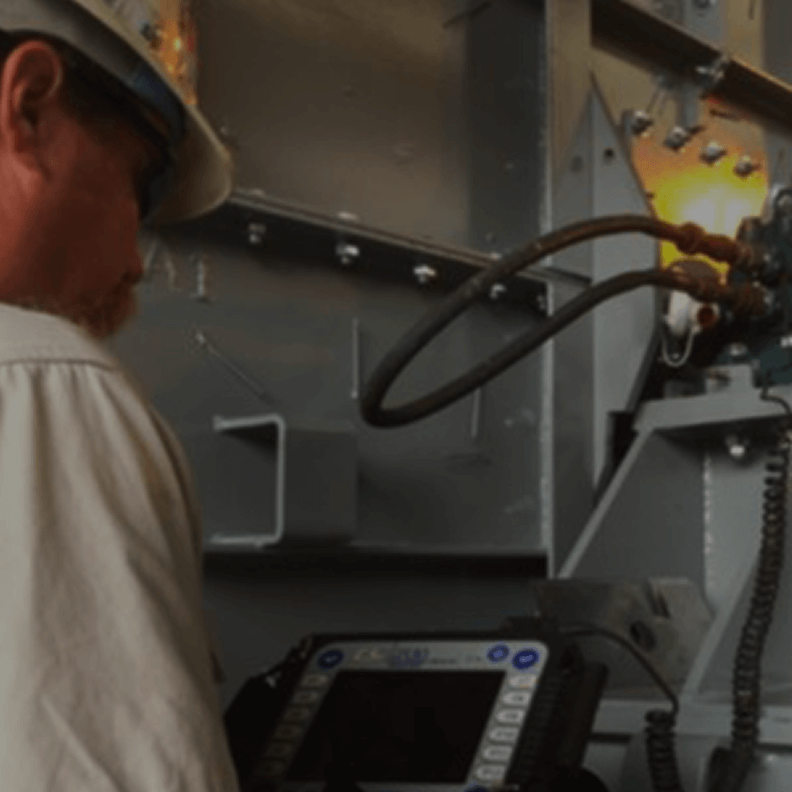

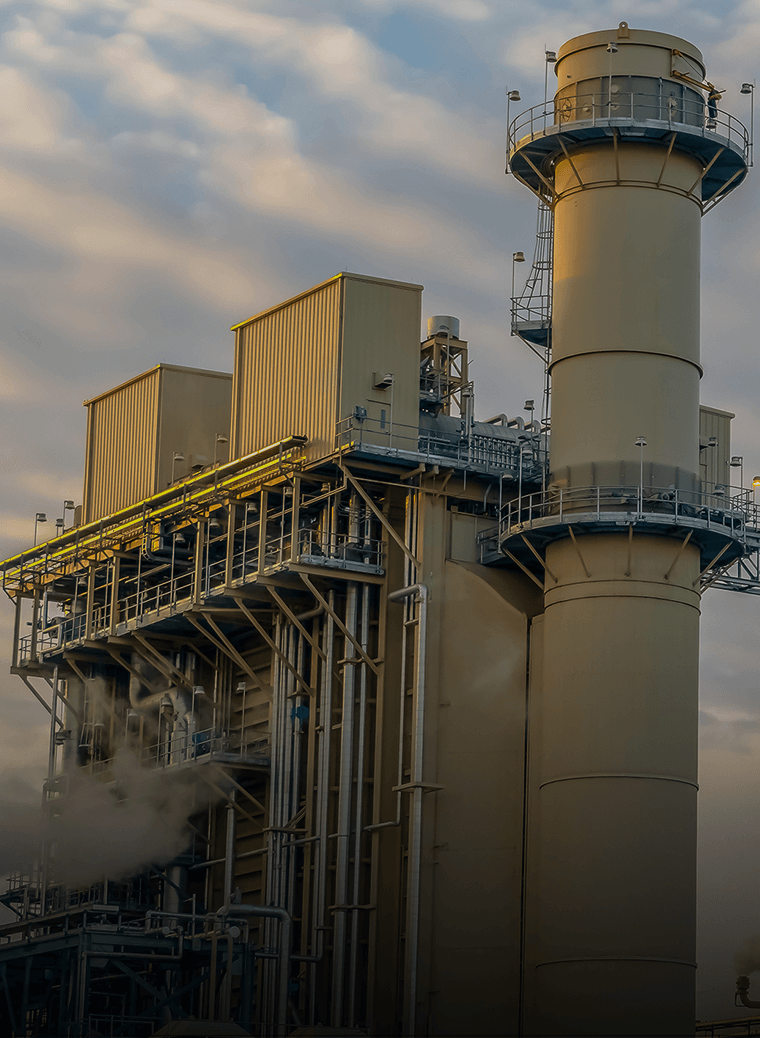

Fast forward to today, Robinson continues to lead with technical expertise and customer service across the many industries it serves including: mining, cement, power generation, steel, fertilizer, oil & gas, cement, pulp & paper, and petrochemical & chemical. To better serve its customers, Robinson has expanded its manufacturing footprint with facilities in Pennsylvania, Florida, Alabama, and Utah as well as expanded its offerings to include best-in-class field service as well as machining and fabrication.

over

130

year

of quality

Over the course of 130+ years, Robinson remains a family-owned business grounded in family values.

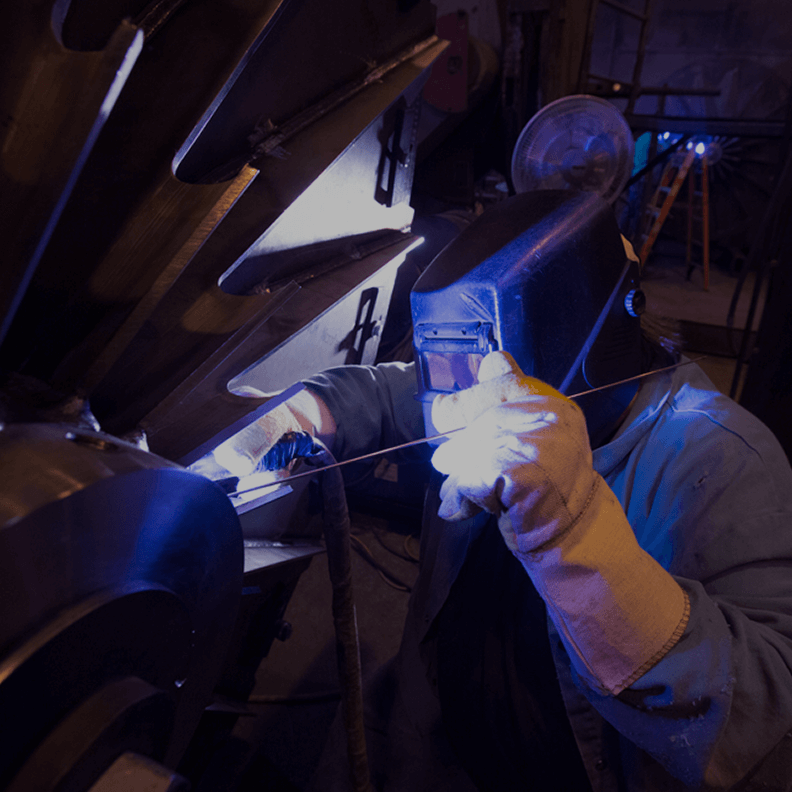

“We were founded on a principle of pride in craftsmanship. While the applications have changed over the years, that underlying principle has not.”

-J.L. Henderson Jr.

1892

Samuel and his son, J.R. Robinson, acquired a machine company in Monongahela, PA, and established the Robinson Machine Company.

1907

Robinson Machine Company became Robinson Ventilating Company, specializing in mine ventilation.

1921

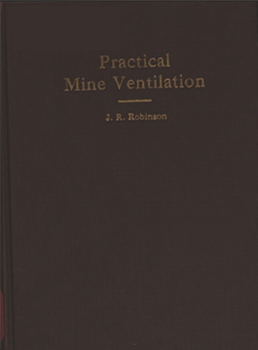

J.R. Robinson publishes the industry-forming book, “Practical Mine Ventilation”. Robinson establishes its facility in Zelienople, PA, which remains the flagship location for the business today.

1924

Robinson fabricators in 1924 posing for a photo.

1976

Robinson Fans opens its second location in Lakeland, Florida.

1986

Robinson Fans establishes Robinson Service in Trussville, Alabama.

1993

Robinson Fans establishes Western US footprint in Salt Lake City, UT.

1997

Robinson Fans breaks ground on 10,000 sq ft. manufacturing facility in Salt Lake City, UT.

2016

Robinson Fans acquires Machine Company in Lakeland, Florida.

2025

To better serve our people and our customers, Robinson launches a unified company, One Robinson