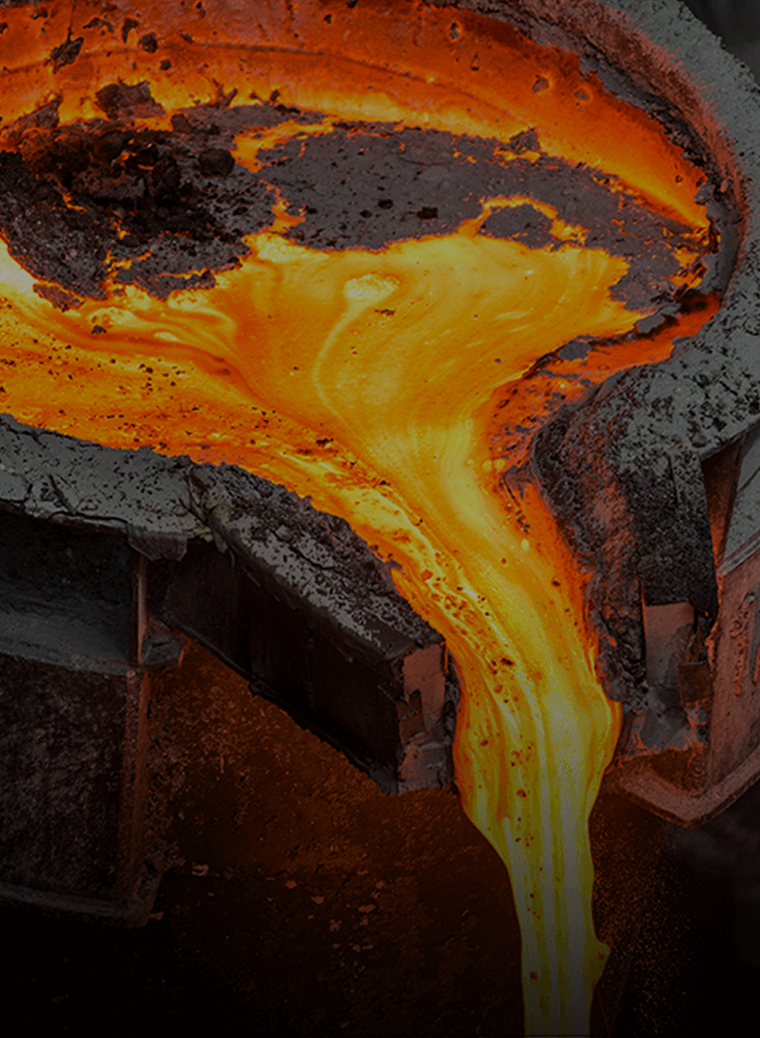

Power Generation

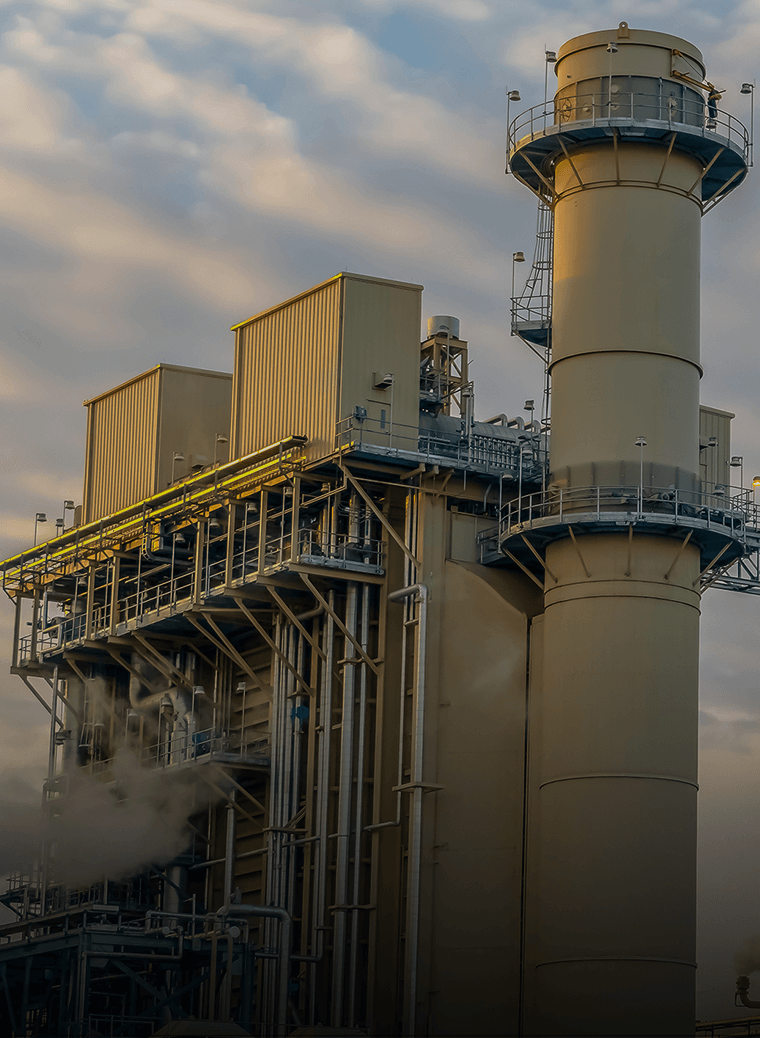

The power demand growth in the United States, which has been largely flat for two decades, is now predicted to grow 50 percent over the next 20 years. The drivers of this dramatic growth include localized manufacturing, industrialization, localized population growth, data centers, electric vehicles, and air conditioning. As the United States utilities providers embrace an “all-in” approach to power generation leveraging natural gas, renewables, coal, and nuclear capabilities, Robinson fans play a critical role in “powering” the future of energy.

Types Of Fans

Used In Power Generation

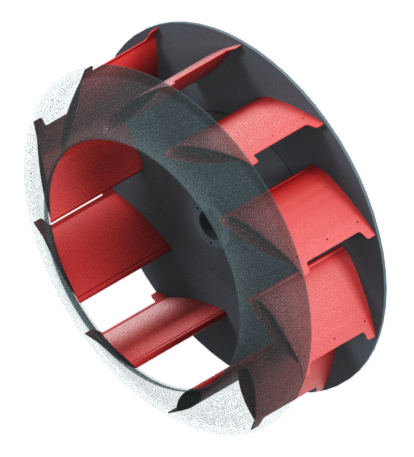

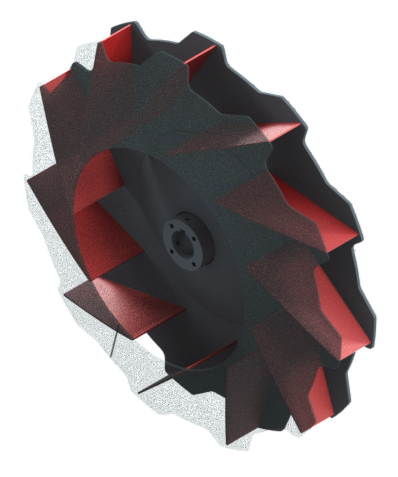

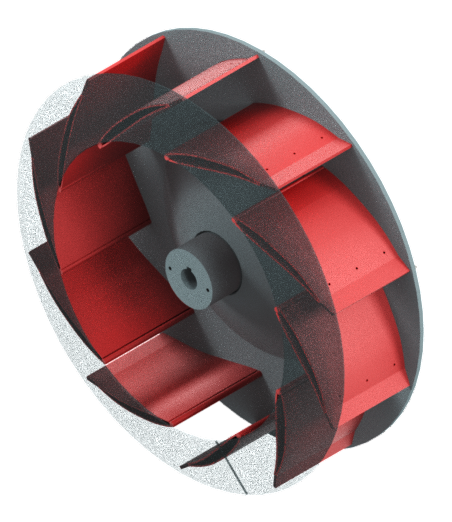

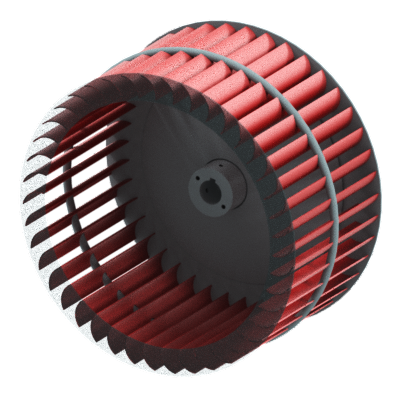

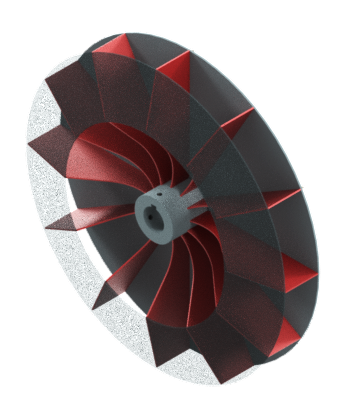

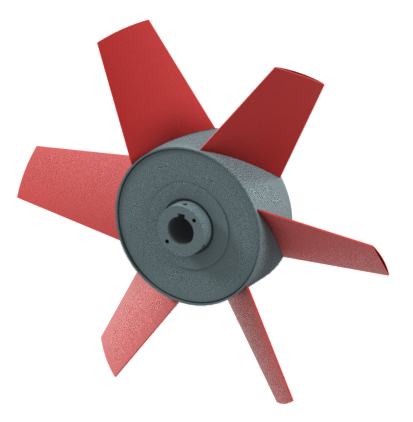

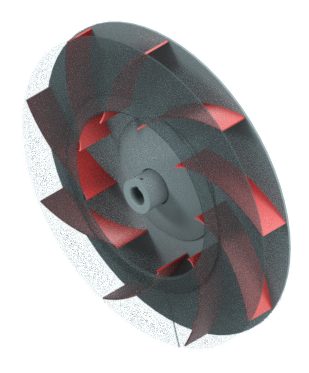

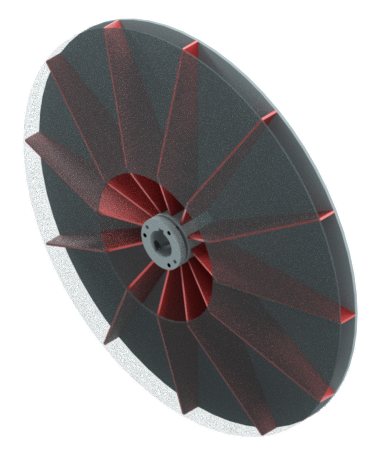

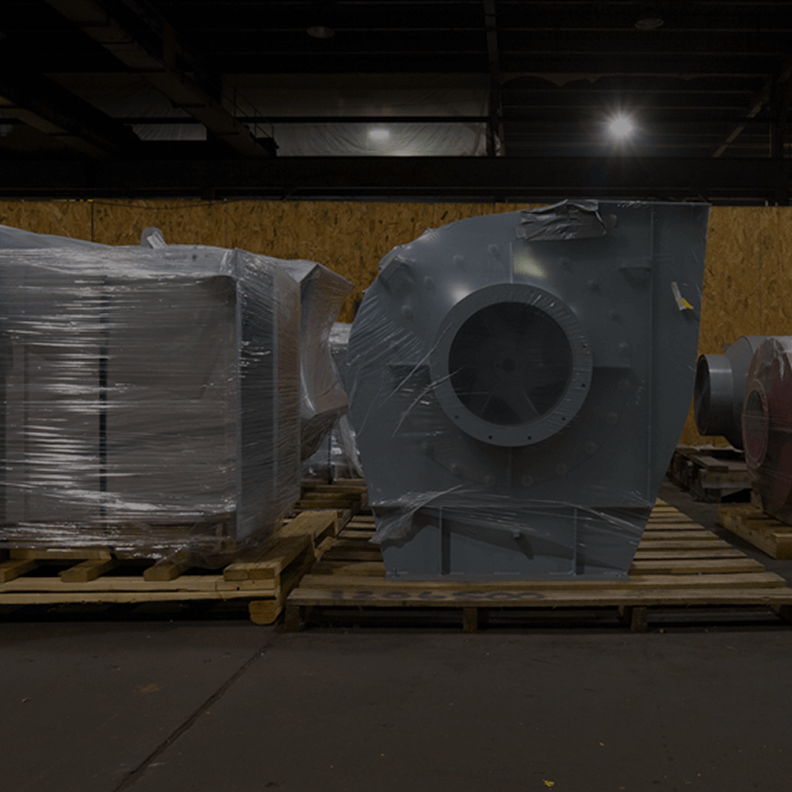

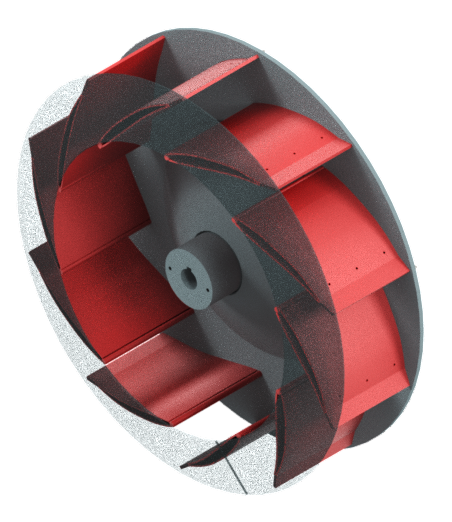

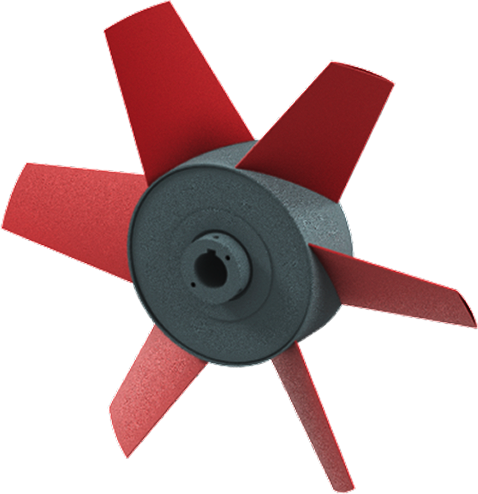

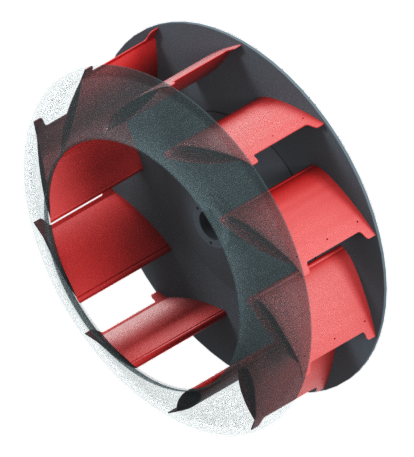

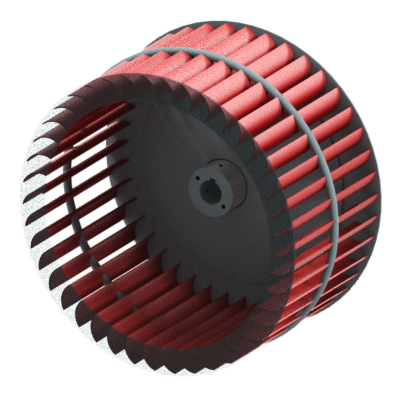

Robinson supplies large induced-draft fans, large forced-draft fans, SCR (Selective Catalytic Reduction) ammonia hot gas fans, as well as other process fans within a power plant. Additionally, we supply fans to non-traditional waste-to-energy plants.

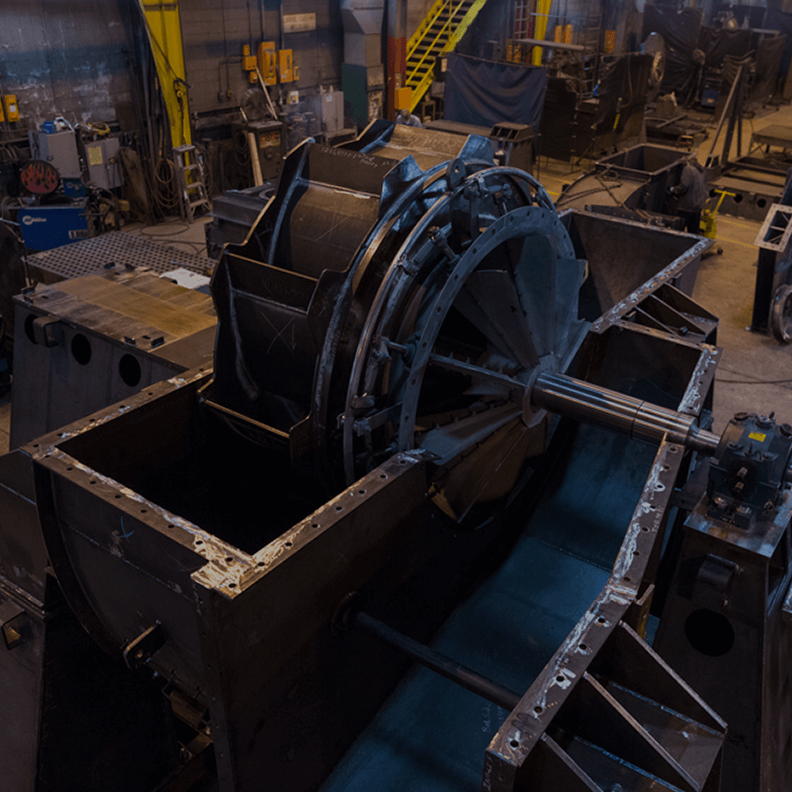

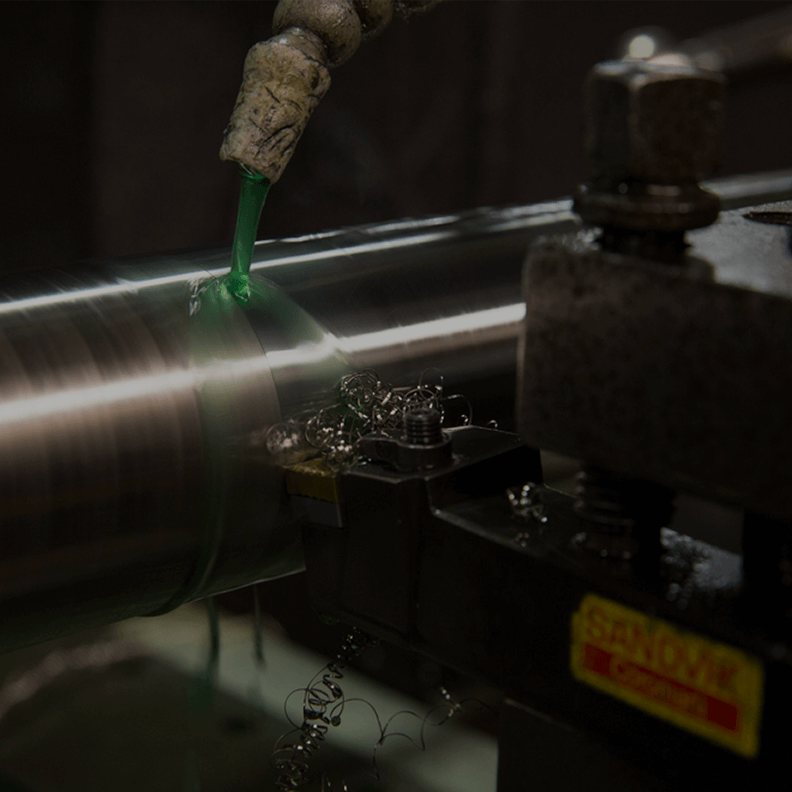

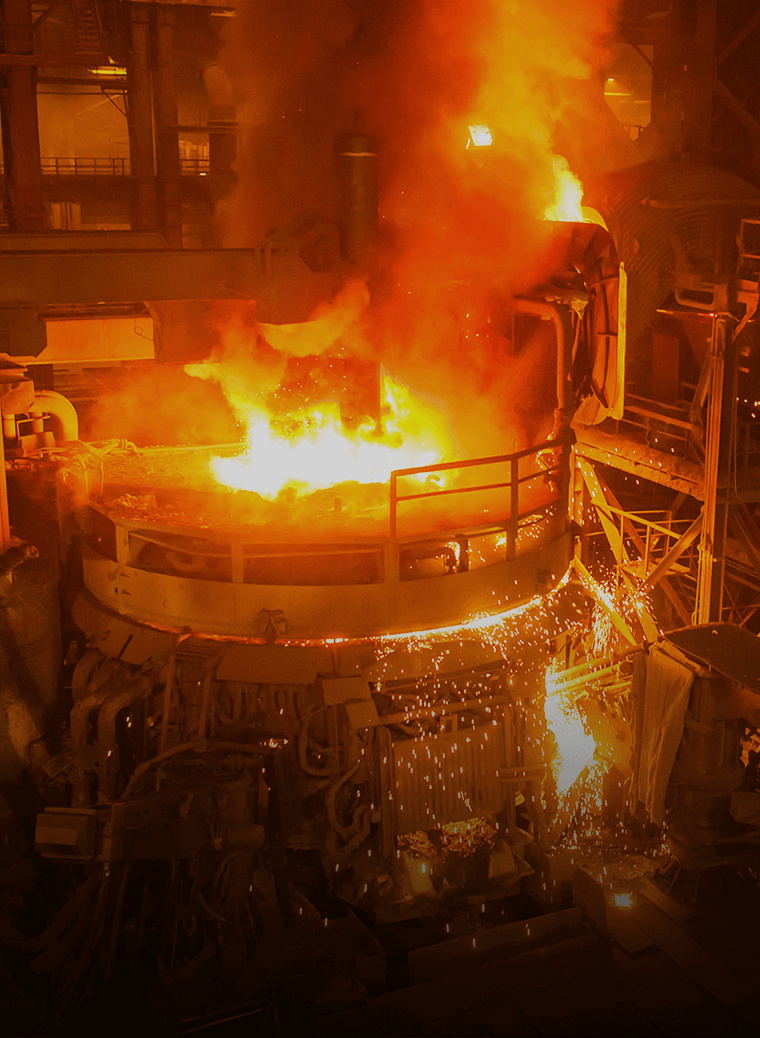

Power Generation Emergency Fan Repair

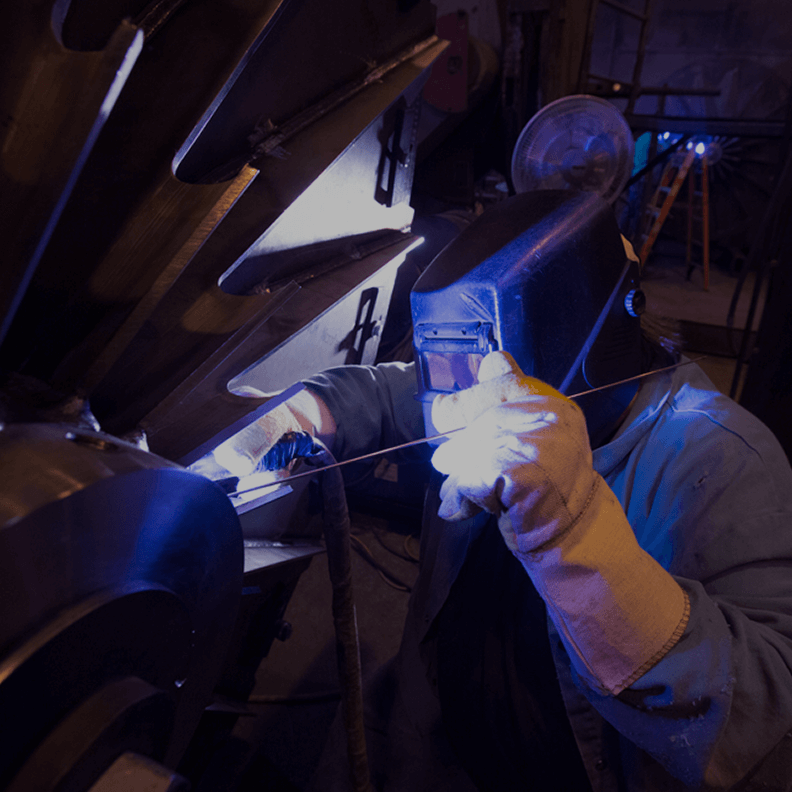

We recognize that a forced outage in the power generation industry is a nightmare. At Robinson, our field service team is here to help you maintain service to your customers, minimize the loss of production time on a critical asset, and support the service and repair of your fan equipment.

Power Generation

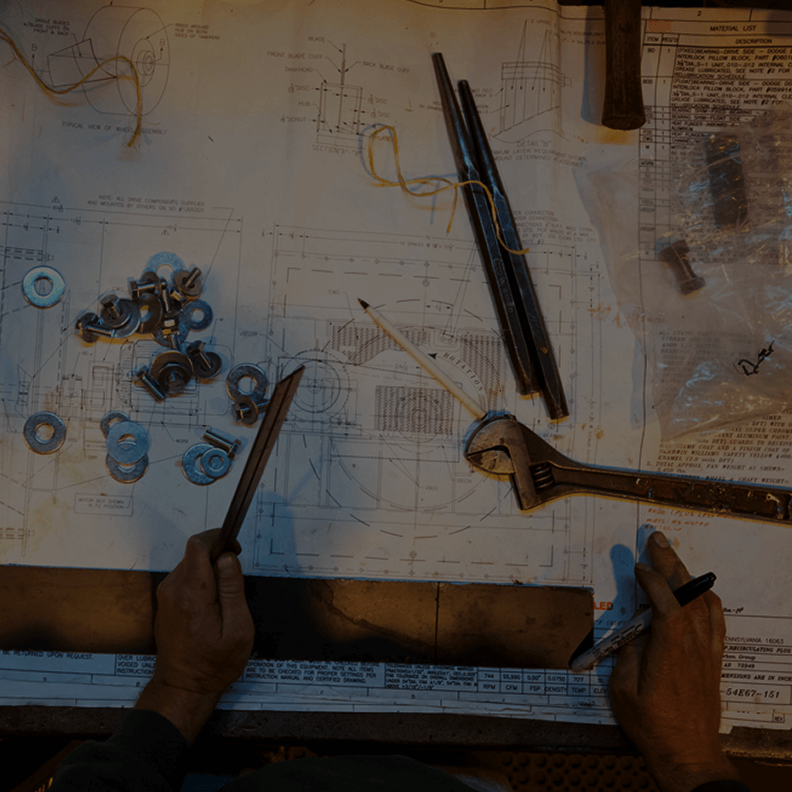

Fan Design

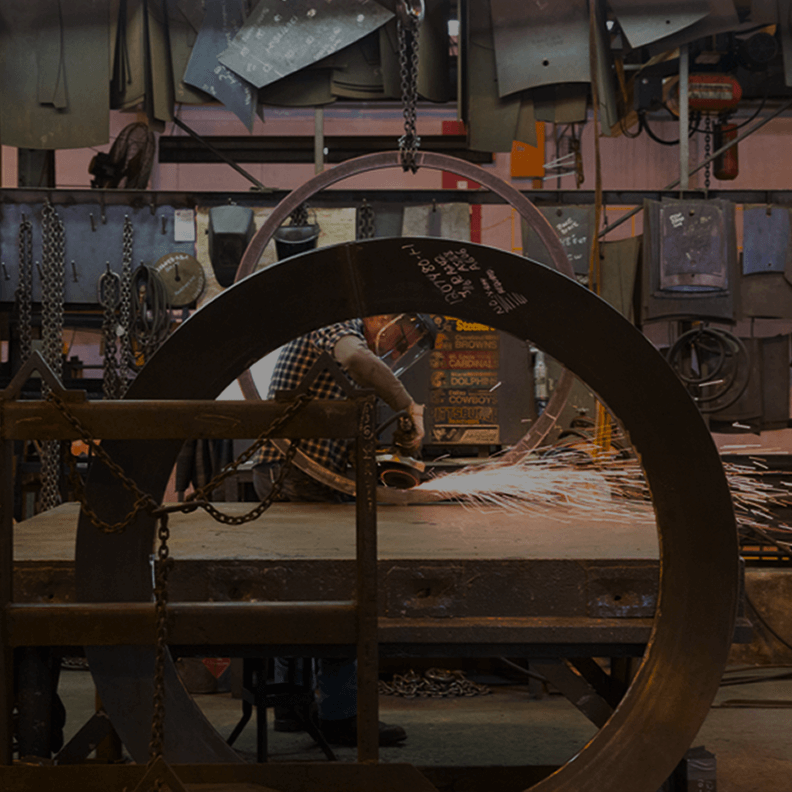

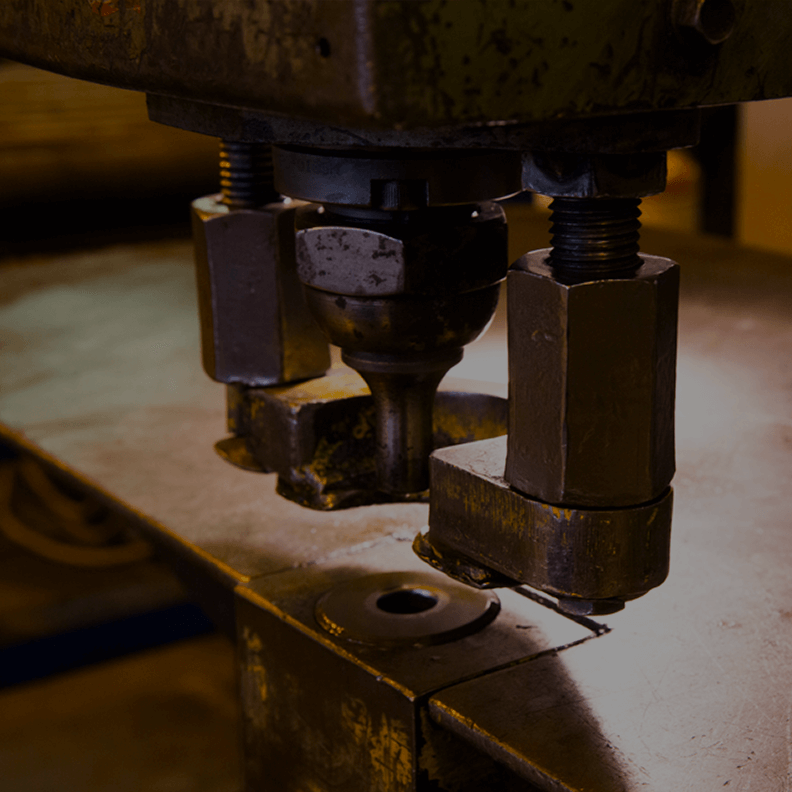

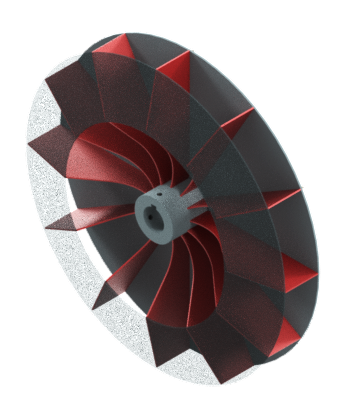

Each power plant is unique in its design, performance requirements, location, and its component equipment. Robinson excels at custom engineering the best-in-class fans to provide superior efficiency and performance for all plant designs and equipment. With the energy boom in natural gas, Robinson is continuously innovating on existing designs to best serve our partners and customers.

Power Generation

Fan Design

Robinson recognizes the importance of minimizing down-time and cost when it comes to providing outstanding service and fan repair. With over 250 combined years of experience, Robinson will evaluate, repair, and often improve the functionality of our customers equipment ensuring they are back online asap.

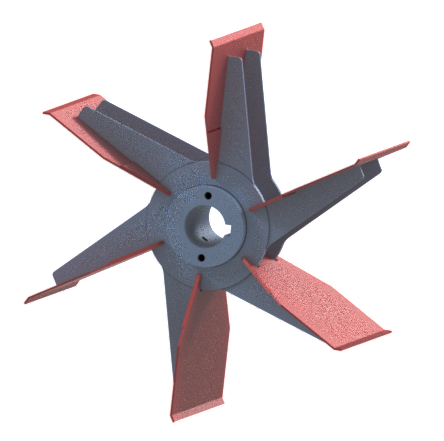

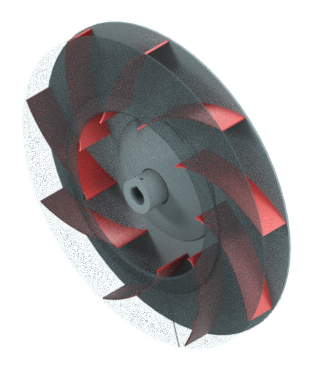

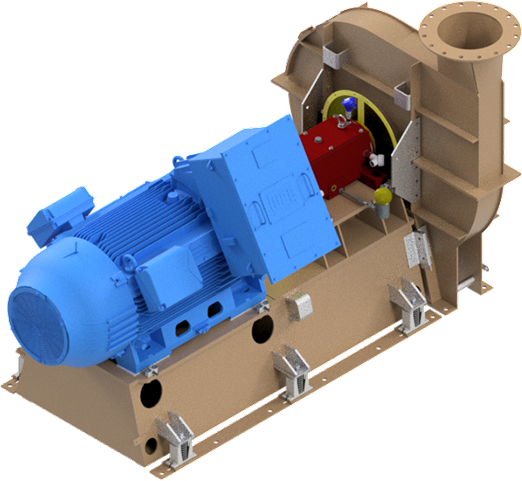

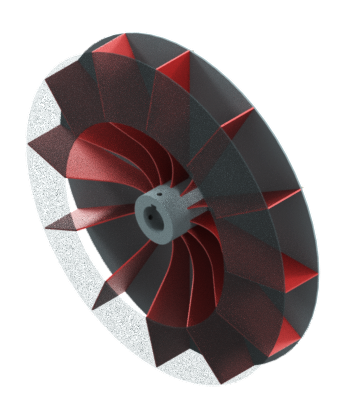

Radial Blade Fan

Case Studies

Waste-to-Energy Industry

Case Studies

Resource Recovery

Case Studies

Utility and Power Industry

Case Studies

Utility and Power Industry

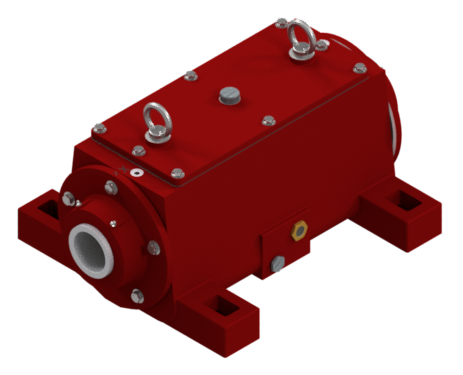

Industrial Fan Products

From replacement fan parts to complete custom-designed industrial fans, we have you covered.

Power Generation Fan Services

Robinson values our market-leading technical expertise as well as our outstanding customer service. We maintain these values in the services we offer to meet all of your industrial fan-related needs.

How

Can We

Help You?

How

Can We

Help You?

We work with

the biggest and best in the world

Why Robinson?

Over 130 years

of history

A sixth-generation

family-owned business,

Robinson offers unmatched

experience

Technical

Expertise &

Customization

standard fan lines, Robinson

customizes every solution to

meet specific customer needs

Top Notch

Customer Service

quality and long-term

relationships

Rapid

Response 24/7

24/7 emergency breakdown

services and a dedicated

Rapid Repair team for a quick turnaround